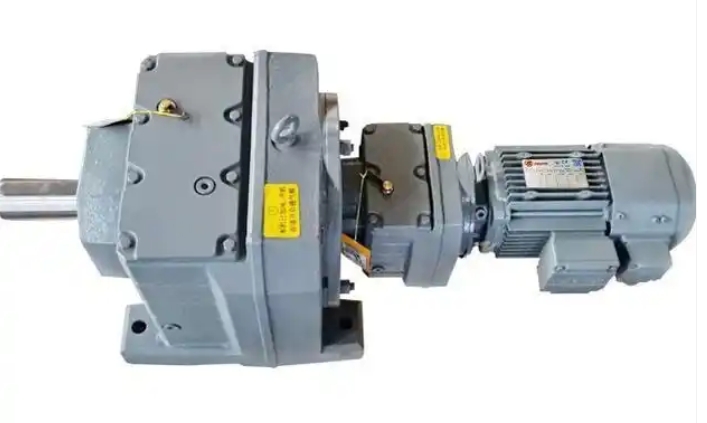

Introduce the working principle of GRF139-17.05-M4-550-IEC-45KW reducer

GRF139-17.05-M4-550-IEC-45KW reducer belongs to helical gear reducer, and its working principle is based on the reduction and torque increasing characteristics of gear transmission. It transmits power through the meshing of internal gears, achieving the function of reducing speed and increasing torque. The following is its detailed working principle:1、 Core transmission principle: gear meshing reduction

1. Input power transmission

Motor drive: The reducer is connected to a motor (with a power of 45kW, in accordance with IEC standards) through a coupling. The high-speed rotational power output by the motor (usually at an input speed of 1450r/min, depending on the number of motor poles) is transmitted to the input shaft of the reducer.

Primary reduction of gear set: Install a small gear (driving wheel) on the input shaft, which meshes with the next stage gear (driven wheel). Due to the small number of teeth on the small gear and the large number of teeth on the driven wheel (the gear ratio determines the reduction ratio), the speed of the driven wheel decreases and the torque increases. For example, if the input shaft small gear has 20 teeth and the driven wheel has 341 teeth (reduction ratio 17.05=341/20), then the output speed is 1/17.05 of the input speed.

2. Multi stage gear transmission (if any)

Some reducers use multi-stage gear sets in series (such as two-stage or three-stage reduction), with each gear further reducing speed and increasing torque. The GRF139 series may be a single-stage or two-stage helical gear transmission, depending on the internal structural design.

Advantages of helical gears: The teeth of helical gears are inclined at a certain angle (helix angle) to the axis. Compared with spur gears, helical gears have smoother meshing, less impact, lower noise, and higher overlap (with more teeth involved in meshing at the same time). They have stronger load-bearing capacity and are suitable for high-power and high torque scenarios.

3. Output power characteristics

After being decelerated by the gear set, the power is transmitted to the output shaft (diameter 550mm), which drives the load equipment (such as conveyor belts, mixers, etc.) at low speed and high torque. A reduction ratio of 17.05 means:

If the motor speed is 1450r/min, the output speed is approximately 1450/17.05 ≈ 85r/min;

The output torque is approximately 17.05 times the motor torque (ignoring transmission efficiency, the actual torque needs to be multiplied by an efficiency coefficient, usually 90% to 95%).

2、 Key structure and functional coordination

1. Gears and shaft systems

Hard tooth surface gear: Adopting carburizing and quenching process, the tooth surface hardness is high (HRC58-62), wear-resistant and impact resistant, and suitable for heavy-duty working conditions.

Shaft support: The input and output shafts are supported on the gearbox housing by rolling bearings (such as tapered roller bearings and cylindrical roller bearings), which bear radial and axial loads to ensure stable rotation of the shaft system.

2. Lubrication system

Oil pool lubrication or forced lubrication:

Low speed or small and medium-sized reducers usually use oil pool lubrication, where the gears are immersed in lubricating oil and splash with oil onto the meshing surfaces and bearings during rotation, achieving lubrication and heat dissipation;

High speed or high-power models may be equipped with an oil pump forced lubrication system, which pressurizes and delivers lubricating oil to various lubrication points through the oil pump to ensure reliable cooling and cleaning.