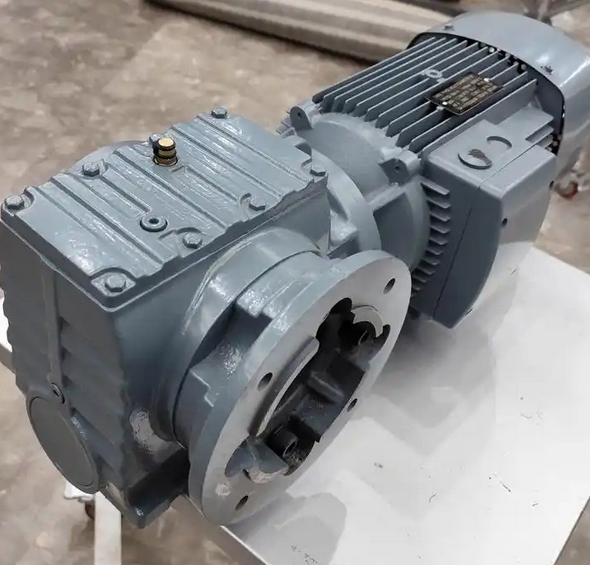

Can the broken teeth of the SEW gearbox in Germany be repaired

It is usually difficult to directly repair gear breakage in German SEW reducers, but some measures can be taken according to the specific situation to solve the problem. The following is a detailed analysis:The reason for the difficulty of routine repairs

Material and process specificity: SEW reducer gears are generally made of high-quality alloy steel and undergo special heat treatment processes such as carburizing and quenching to obtain good strength, hardness, and wear resistance. This material and process make the internal structure and performance of the gear uniform and stable. Once the tooth is broken, it is difficult to restore its original performance and accuracy through conventional welding or simple repair methods.

High precision requirements: As a high-precision transmission equipment, SEW reducers usually have high manufacturing accuracy for their gears. Even if some repair methods are used after tooth breakage, it is difficult to ensure that the repaired gears can meet the original precision requirements, such as tooth profile accuracy, tooth profile accuracy, tooth pitch accuracy, etc. If the accuracy cannot be guaranteed, it will cause problems such as poor meshing, vibration, and increased noise during the operation of the gear, which will affect the overall performance and service life of the reducer.

possible solutions

Replacing gears: If the tooth breakage is severe, it is generally recommended to replace the gears with new ones and strictly follow the installation requirements for installation and debugging to ensure the normal operation of the gears.

Partial repair: For some cases where the tooth breakage is not too severe and other parts of the gear are basically intact, some local repair methods can be considered. For example, for small area tooth tip fractures, laser cladding can be used for repair. Laser cladding is an advanced surface repair technology that can accurately fuse metal powder onto the broken teeth without affecting the overall performance of the gear, restoring the tooth profile. But this method requires professional equipment and technicians, and the repaired effect needs to undergo strict testing and verification.