Electric roller, external motor, unpowered roller, heat-resistant and wear-resistant, tape width 300, diameter 500

In the field of industrial conveying equipment, electric drums, external motors, unpowered rollers, and heat-resistant and wear-resistant designs for specific specifications (such as tape width of 300mm and diameter of 500mm) constitute the core components of modern efficient and reliable material conveying systems. These components not only improve production efficiency, but also ensure safety and stability during operation, especially in conditions with special material requirements or extremely harsh working environments. Below, we will delve into the technical characteristics, application scenarios, advantages, and selection criteria of these key components.

###Electric drum: the source of power, intelligent drive

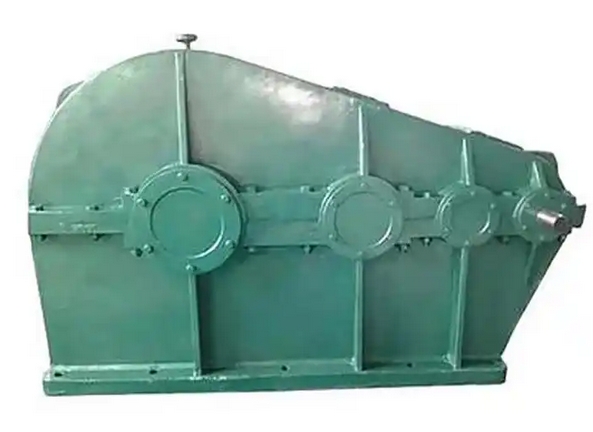

As the heart of the conveyor system, the electric drum integrates a motor, a reduction device, and a drum, directly providing power to the conveyor belt. Compared to traditional driving methods, electric rollers have the advantages of compact structure, easy installation, and low maintenance costs. For heat-resistant and wear-resistant electric drum, its shell and key internal components are made of special alloys or high-temperature resistant and wear-resistant materials, ensuring stable operation in high temperature or high friction environments, effectively extending the service life of the equipment. In addition, some high-end electric rollers are equipped with intelligent control systems that can automatically adjust the output power according to the conveying load, achieving energy conservation and consumption reduction.

###External motor: flexible and efficient, easy to maintain

The external motor is connected to the drum through couplings or chains to provide power for the conveyor belt. This design approach makes the maintenance of the motor and drum more independent. Once a fault occurs, it can be quickly replaced or repaired, reducing downtime. At the same time, the external motor has a larger heat dissipation space, which is beneficial for the motor to maintain normal operating temperature in high temperature environments, and improves the overall reliability and stability of the system. For specific application scenarios, such as those that require frequent adjustment of conveying speed or direction, using an external motor in conjunction with a frequency converter can achieve stepless speed regulation and precise control, meeting diverse production needs.

###Non powered roller: stable support, reducing resistance

Non powered idlers, as important supporting components of conveyor belts, are mainly used to support the conveyor belt and the materials on it, and guide the conveyor belt to run in the predetermined direction. The design focus of non powered rollers is to reduce operating resistance and improve conveying efficiency. Adopting high-quality bearings and sealing structures ensures flexible rotation, low noise, and long service life of the rollers. In terms of heat and wear resistance, by selecting high-temperature resistant materials and optimizing structural design, non powered rollers can adapt to high temperature and high wear environments, reducing failures caused by thermal expansion or wear. In addition, a reasonable layout and spacing of the rollers are also key factors in ensuring the stable operation of the conveyor belt and reducing energy consumption.

###Heat resistant and wear-resistant design: to cope with extreme working conditions

For a conveyor system with a tape width of 300 millimeters and a diameter of 500 millimeters, heat-resistant and wear-resistant design is particularly important. The conveyor belt and its supporting components need to have characteristics such as high temperature resistance, wear resistance, and corrosion resistance to ensure stable operation under extreme working conditions.