The "little fresh meat" in the reducer family

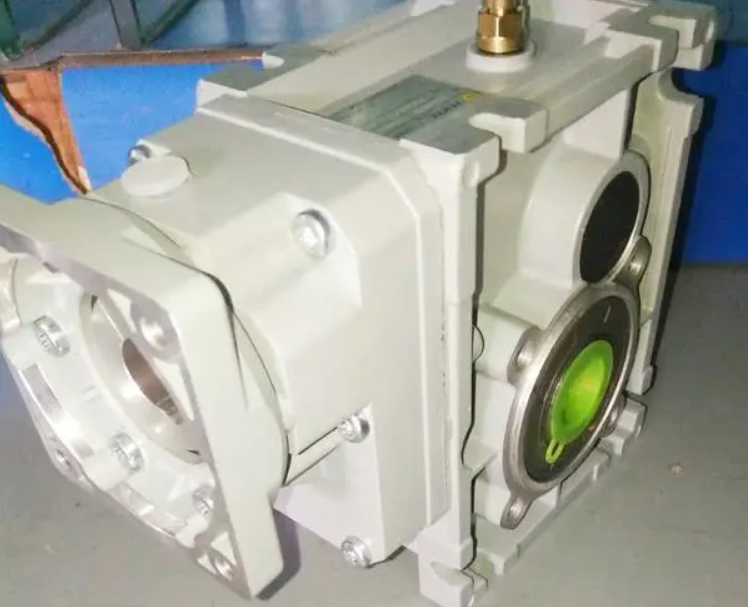

When it comes to fresh meat, the words that appear in your mind may be "little white face", "young", "handsome", and so on. But there is also such a small fresh meat in the family of gearboxes, which is the TKM hard tooth surface gearbox that we will introduce today. This reducer is made of high-quality aluminum shell gold, and its lightweight body is not easy to rust.

Nowadays, this type of reducer is commonly used to match servo motors. The flange connected to the servo motor is usually similar to that of a regular reducer. Generally, the flange connecting the servo motor to the reducer is quite special, and the connection method depends on the servo motor produced by each manufacturer, usually in the form of a flange. This TKM hyperbolic reducer has some unique advantages, such as its construction being a hypoid gear transmission with a large transmission ratio. And this type of hard tooth reducer has a large output torque, high transmission efficiency, and is also relatively energy-saving and environmentally friendly. Although its size is small, it runs quite smoothly and has low noise during operation. It is very different from the four series reducers in that it can adapt to all-round installation, which means that all six installation methods of M1-M6 can be met without any restrictions.

In addition, the installation method of this TKM hard tooth surface reducer is fully compatible with the TNRV series worm gear reducer, and the TKB series reducer is also fully compatible with the W series worm gear reducer. In terms of structure, a modular design scheme is utilized to enable this reducer to be combined with other series of reducers, thereby meeting the requirements of transmission conditions.

During the selection or use process, Xu Yasuo considers the working conditions of the equipment itself. Here are three situations:

1. Uniform impact load, allowing for an inertial acceleration coefficient Fa ≤ 0.2, such as on a conveyor belt;

2. Medium impact load, with an allowable inertia acceleration coefficient Fa ≤ 3, such as for medium-sized mixers;

3. Heavy impact load, with an allowable inertia acceleration coefficient Fa ≤ 10, such as a convex shaft press.

For example, if the required torque for the driven equipment is 200Nm, working for 8 hours a day, uniformly impacting the load, and starting at a frequency of 400 times/hour, the reducer requires FA1 flange installation, the reducer requires an input speed of 900r/min, and the input speed n2=6r/min. By checking the performance parameters, it can be concluded that in this situation, only the form of three-stage transmission can be selected. By querying the coefficient chart again, you can choose to use a coefficient of 1.05.

I personally feel that the appearance of this gearbox still has a bit of a "fresh meat" feeling.