Cycloidal gear reducer installation drawing and precautions

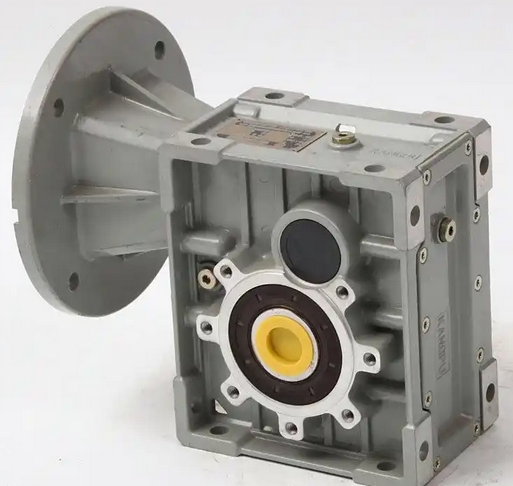

The cycloidal reducer is a commonly used mechanical transmission device with the advantages of high transmission efficiency, strong load-bearing capacity, and low noise. In the fields of manufacturing and machining, cycloidal reducers are widely used. However, the correct installation and use methods have an important impact on the working effect and life of the cycloidal reducer. Below, we will introduce the installation diagram and precautions of the cycloidal reducer to help you use the cycloid reducer correctly.  1. Cycloidal reducer installation diagram

Step 1: Check the equipment drawings carefully. Before installing the cycloid reducer, you need to carefully check the equipment drawings to understand the structure, size and installation location of the cycloid reducer. At the same time, it is also necessary to clarify the usage environment and requirements of the machine.

Step 2: Check the parts. During the installation process, it is necessary to check whether the parts of the cycloidal reducer are complete and confirm. Check whether each component is normal, whether there is any damage, deformation, etc., and clean and lubricate each component.

Step 3: Install the base. After confirming that all components of the cycloidal reducer are correct, the base needs to be installed on the equipment. When installing the base, you need to use bolts to fix the base to the device, and make sure the base is flat, stable, and perpendicular to the ground.

Step 4: Install the gear. After installing the gear on the base, you need to install the gear on the base through the bearing sleeve and connect the gear to the output shaft of the reducer.

Step 5: Install the oil seal and fill with grease. After the gear is installed, you need to install the oil seal of the cycloidal reducer and fill with grease. First, you need to clean the residue inside the reducer, then install the oil seal on the input end of the reducer and inject an appropriate amount of grease inside the reducer.

Step 6: Connect the motor and cycloid reducer. After the cycloid reducer is installed, you need to connect the output shaft of the cycloid reducer to the input shaft of the motor. When connecting the motor, attention needs to be paid to positioning and alignment to ensure balance and synchronization of the transmission system. 2. Precautions for installing the cycloidal reducer (1) The installation location of the cycloidal reducer needs to be easy to maintain and repair, and must meet the requirements for safe production. (2) During the installation process of the cycloidal reducer, attention should be paid to ensuring that the various parts of the machine are not subject to impact or severe vibration. (3) The installation and use of the cycloid reducer requires professionals to operate it and operate it in accordance with the prescribed order and requirements. (4) During the installation process of the cycloidal reducer, attention should be paid to that each bolt on the machine must be tightened to the specified torque. (5) The sealing and lubrication of the cycloidal reducer are also issues that need attention during the installation process. The machine needs to be refueled and lubricated to ensure that it remains stable during use. The correct installation and use of cycloidal reducers has an important impact on the performance and life of the machine. Therefore, during the installation and use of the cycloidal reducer, it is necessary to carefully review the device drawings and precautions, and carefully formulate operation plans and programs to ensure the stable and efficient operation of the cycloidal reducer.