Customization process of MVE-155-L2-7-P0 precision planetary gearbox

The customization of MVE-155-L2-7-P0 precision planetary gearbox is a complex but orderly process that requires close cooperation between customers and manufacturers to meet specific application requirements. Intended to provide customers with high-quality products that best meet their needs.

The first step is requirement communication and evaluation. Customers first need to clarify their own application scenarios and performance requirements for the gearbox, such as required torque, speed, accuracy, installation method, working environment, etc. The manufacturer's technical team will have in-depth communication with customers to understand these requirements and evaluate their feasibility and rationality. For example, an automated production line manufacturer needs a gearbox that can operate stably under high-speed, high load, and limited space conditions. The technical team will make a preliminary judgment on the difficulty and direction of customization based on these specific requirements.

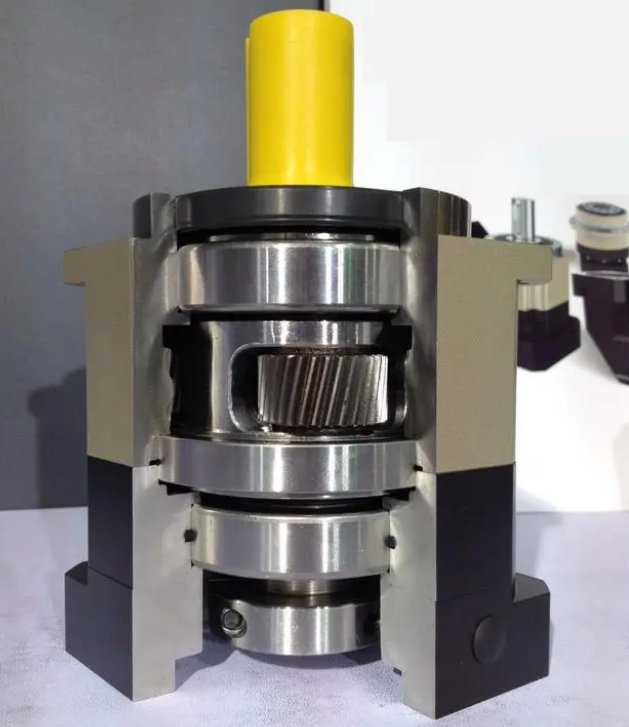

The second step is scheme design. Based on customer needs, the manufacturer's engineers will design preliminary customized solutions. This includes the structural design of the reducer, gear parameters, material selection, lubrication method, etc. At the same time, professional design software will be used for simulation analysis to verify the feasibility and performance indicators of the plan. For example, in order to meet the demand for high torque, special gear tooth profiles and materials may be used, or the number of gears may be increased to improve the reduction ratio.

Step three, sample production and testing. According to the design plan, the manufacturer will produce a small number of samples. These samples will undergo rigorous performance testing in a laboratory environment, including torque testing, speed testing, accuracy measurement, noise detection, temperature rise testing, etc. If the test results do not meet expectations, adjustments and optimizations will be made to the design plan. For example, if excessive noise is found during testing, the meshing accuracy of the gears may be adjusted or the lubrication system may be optimized.

Step four, customer confirmation and improvement. Feedback the test results to the customer, and the customer will confirm whether the requirements are met based on the actual situation. If the customer provides further improvement suggestions or discovers new problems, the manufacturer will make further improvements and optimizations to the solution until the customer is satisfied.

Step five, mass production. Once the sample is confirmed by the customer, the manufacturer will begin mass production. During the production process, strict quality control standards will be followed to ensure that each reducer meets customized requirements. At the same time, key links in the production process will be monitored and inspected to ensure the stability of product quality.

Step six, quality inspection and delivery. Before the finished product leaves the factory, a comprehensive quality inspection will be conducted, including visual inspection, dimensional measurement, performance retesting, etc. Only gearboxes that have passed all tests can be delivered to customers. At the same time, detailed user manuals and maintenance guides will be provided to customers.

For example, our previous high-end CNC machine tool manufacturer customized MVE-155-L2-7-P0

The precision planetary reducer has successfully achieved the requirements of high precision, high speed, and low noise through demand communication, scheme design, sample testing, and multiple improvements, greatly improving the machining performance of CNC machine tools.