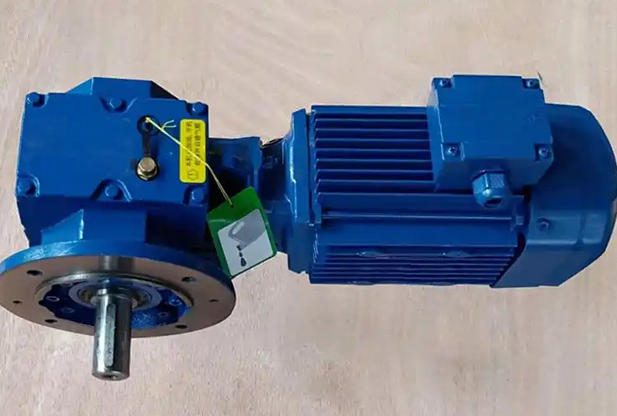

XLED84-291-3KW reducer BLED20-289-0.37KW for belt conveyor use

In the field of industrial production, as an important transmission equipment, the stability and reliability of the performance of the reducer directly affect the operational efficiency of the entire production line. Especially in mechanical equipment such as belt conveyors that require continuous and efficient operation, the selection and use of reducers are crucial. This article will take the use of XLED84-291-3KW reducer BLED20-289-0.37KW on belt conveyors as an example to explore in depth the application and optimization strategies of reducers in belt conveyors.

1、 Performance characteristics of XLED84-291-3KW reducer and BLED20-289-0.37KW reducer

The XLED84-291-3KW reducer has been widely used in industrial production due to its high torque, high efficiency, low noise, and long service life. Its internal structure is compact, easy to install and maintain, capable of withstanding large loads and impacts, and suitable for various harsh working environments. The BLED20-289-0.37KW reducer, with its small size, light weight, high precision, and smooth operation, has become an indispensable transmission device in belt conveyors.

2、 Application of reducer in belt conveyor

In a belt conveyor, the main function of the reducer is to achieve transmission between the motor and the pulley by reducing the speed and increasing the torque. The application of XLED84-291-3KW reducer and BLED20-289-0.37KW reducer in belt conveyors is mainly reflected in the following aspects:

1. Improve transmission efficiency: Through the transmission of the reducer, the speed of the motor is matched with the speed of the pulley, thereby achieving efficient and stable transmission effect. At the same time, the gear transmission system inside the reducer can reduce energy loss during the transmission process, further improving transmission efficiency.

2. Reduce operating noise: The gears inside the reducer are precision machined and lubricated, greatly reducing the noise generated during operation. This not only improves the working environment, but also enhances the operational stability of the equipment.

3. Enhance load-bearing capacity: XLED84-291-3KW reducer and BLED20-289-0.37KW reducer have high load-bearing capacity and can withstand various loads and impacts generated by belt conveyors during operation. This ensures the stable operation of the equipment in harsh working environments.

3、 Optimization strategy of reducer in the use of belt conveyor

In order to fully utilize the role of the reducer in the belt conveyor, improve its operating efficiency and stability, we can adopt the following optimization strategies:

1. Reasonable selection: Choose the appropriate reducer model and parameters based on the actual needs and working environment of the belt conveyor. Ensure that the torque, speed, noise and other indicators of the reducer meet the usage requirements.

2. Regular maintenance: Regularly inspect, clean, lubricate, and tighten the gearbox to ensure its normal operation. At the same time, timely handling of discovered faults and problems to avoid the expansion of faults.