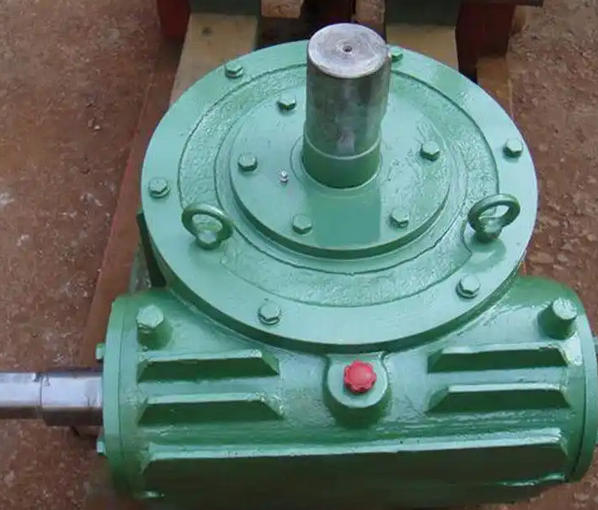

Can you provide an optimization design case of WHC280-20-I worm gear reducer

The requirements for the optimization design case of WHC280-20-I worm gear reducer, combined with relevant technical data, are explained in detail from the aspects of arc tooth cylindrical worm gear design optimization, selection of high-strength anti friction materials, lubrication management, and load controlOptimization of design for circular arc cylindrical worm gear

The WHC series reducer adopts a cylindrical worm gear with a circular arc cross-section and a conjugate circular arc worm gear tooth shape. By increasing the comprehensive curvature radius of the meshing area through convex concave meshing, the tooth surface stress is reduced and the bearing capacity is improved. When optimizing the design, the following parameter combinations can be referred to:

Modulus and head count: By adopting a multi head count (such as 21=2 or 4) and a small modulus design, the load-bearing capacity can be significantly improved (for example, when 21=4, the load-bearing capacity is about 160% higher than that of the involute worm).

Displacement coefficient: Increasing the displacement coefficient (x2=0.5~1.5) can improve the bearing efficiency, but it is necessary to avoid the tip of the worm gear teeth becoming sharp. The general recommendation is x2=0.7~1.2, which can be adjusted according to the number of worm gear teeth.

Tooth angle and arc radius: Choosing a smaller tooth angle (such as 20 °~25 °) and tooth profile arc radius can improve the shape of the meshing contact line and reduce friction loss.

Selection of high-strength friction reducing materials

Worm material: Typically, quenched steel (such as 20CrMnTi) is used to improve surface hardness (HRC58~62) and wear resistance through carburizing and quenching treatment.

Worm gear material: Bronze (such as ZCuSn10P1) or aluminum iron bronze are preferred, as they have excellent anti friction performance and are suitable for the sliding friction conditions of worm gears.

Optimization of lubrication management

Lubricating oil selection: Use specialized lubricating oil for worm gears (such as L-CKC 220 # or 320 #), and choose the viscosity grade according to the working temperature.

Lubrication method: When using oil bath lubrication, it is necessary to ensure that the oil level is at the centerline of the oil window; Intelligent fuel injection system can be configured for high-speed working conditions to dynamically adjust the fuel quantity according to the load.

Oil change cycle: It is recommended to replace the lubricating oil once a year or after running for a total of 2000 hours to avoid an increase in friction coefficient caused by oil aging.

Load control strategy

Load matching: Avoid "big horse pulling small car" and ensure that the actual load is within the range of 70%~90% of the rated load. If it is consistently below 50%, adjust the transmission ratio. If overloaded, replace the gearbox with a larger specification.

Buffer measures: For impact loads (such as crushers), elastic couplings (such as plum blossom couplings) can be installed between the motor and reducer to reduce peak loads by 30% to 50%.

Coaxiality control: During installation, it is necessary to ensure that the coaxiality deviation of the transmission link is ≤ 0.02mm/m to avoid local overload caused by unbalanced load.