What are the performance characteristics of WPDX50-60-0.12KW worm gear reducer

The WPDX50-60-0.12KW worm gear reducer, as a small and specific speed ratio transmission equipment, is designed with its performance characteristics closely centered around the core requirements of "low power, large reduction ratio, and high adaptability", as follows:1、 Core transmission characteristics: precise deceleration suitable for low-power scenarios

Single stage large reduction ratio, compact structure

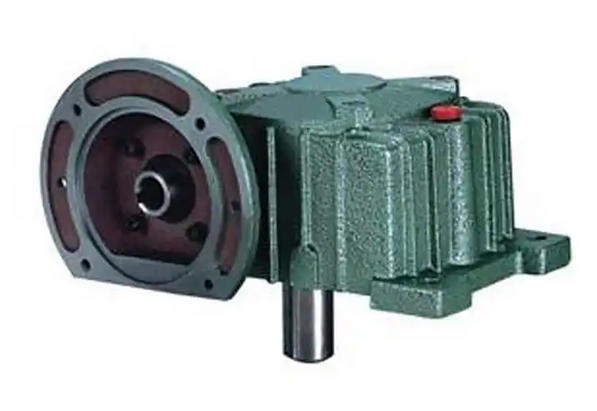

The reduction ratio of this model is 1:60, and the conversion from high-speed input to low-speed output of the motor can be achieved through single-stage meshing of the worm gear, without the need for a multi-stage transmission structure. Compared to gear reducers with the same reduction ratio, it has a smaller volume (with "50" as the center distance specification, belonging to small reducers) and can adapt to small mechanical equipment with limited installation space.

Combined with a 0.12KW low-power motor, it can accurately output low-speed and high torque power (for example, when the input speed is 1440r/min, the output speed is about 24r/min), meeting the needs of small equipment for "slow operation and stable driving" (such as small conveyor belts and micro mixing devices).

Smooth transmission and extremely low noise

Worm gear meshing belongs to surface contact transmission (rather than linear contact of gear transmission), with a larger force area, less vibration and impact during the transmission process, and smoother operation.

In addition, the 0.12KW input power itself is relatively small, without the load impact of high-power transmission, and the noise during equipment operation can be controlled at a low level (usually ≤ 65dB), which is suitable for noise sensitive scenarios (such as laboratory equipment, small food processing machinery).

2、 Structure and Safety Characteristics: Reliable Adaptation to Small Devices

Equipped with self-locking function, safe operation

Worm gear transmission has reverse self-locking in most cases (when the worm lead angle is less than the equivalent friction angle of the meshing surface), that is, it can only drive the worm wheel to rotate through the worm gear, and the worm gear cannot drive the worm wheel in reverse.

This feature is particularly important for small equipment, such as small lifting devices and inclined conveying equipment, which can rely on self-locking to prevent the load (such as heavy objects, materials) from reversing due to their own weight when stopped, without the need for additional braking devices, simplifying the structure and improving safety.

Simple structure and easy maintenance

The small worm gear reducer has a small number of components (mainly composed of worm gear, worm wheel, housing, bearings, and oil seals), a modular overall structure, and low difficulty in assembly and disassembly.

Daily maintenance mainly involves regular checks of the lubricating oil level (usually lubricated with grease or a small amount of mechanical oil), without the need for complex maintenance procedures, and is suitable for the "low maintenance cost" needs of small equipment.