What does the slight impact load specifically refer to in the load characteristic adaptation principle of ZFY560-100-3 reducer?

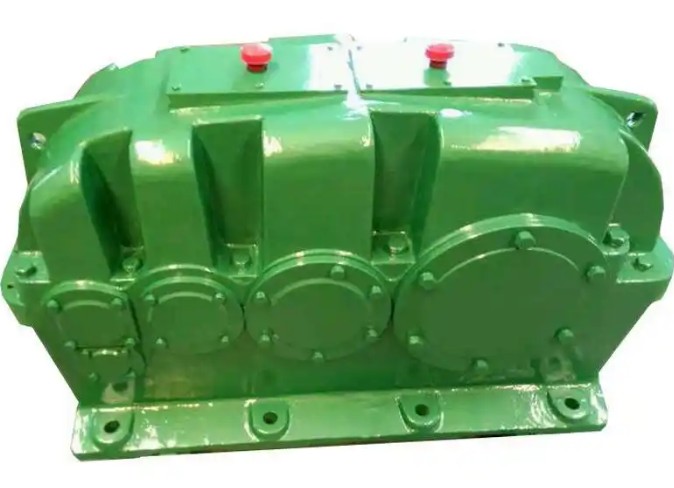

In the load characteristic adaptation principle of ZFY560-100-3 hard tooth surface cylindrical gear reducer, slight impact load refers to the small and low-frequency fluctuations of the load during operation, without severe instantaneous impact, and the peak load will not exceed 1.2-1.5 times the rated torque (corresponding to the working condition coefficient K=1.2-1.5), belonging to the load type between constant load and moderate impact load.1、 Core characteristics of slight impact load

1. Small fluctuation amplitude of load

The actual working torque fluctuates slightly around the rated torque, usually within the range of ± 10% to ± 30%, without sudden peak load impact. For example, load fluctuations caused by uneven distribution of materials on a constant speed conveyor, and resistance changes caused by slight clumping of materials in mixing equipment.

2. Low impact frequency

The frequency of load fluctuations is low, with no more than 10 impacts per hour, and the impact duration is short (in milliseconds), without forming continuous alternating impact loads.

3. Weak damage to the gearbox

This type of load will not cause instantaneous overload on the gear meshing surface, nor will it generate severe impact stress on the bearing. The damage under long-term operation is mainly fatigue wear, rather than impact damage.

2、 Typical operating conditions for adaptation

The slight impact load scenarios suitable for ZFY560-100-3 gearbox include:

1. Conveyor machinery: belt conveyor (medium material uniformity), scraper conveyor (no large block material jamming), bucket elevator (stable feeding);

2. Mixing machinery: low-speed liquid mixer, paste mixer (materials without hard lumps), fertilizer mixing equipment;

3. Building materials machinery: small roller presses, ceramic tile body conveyors, and conveyor rollers for gypsum board production lines;

4. General machinery: fans, water pumps (non variable frequency start, low start stop frequency), and feed mechanisms for ordinary machine tools.