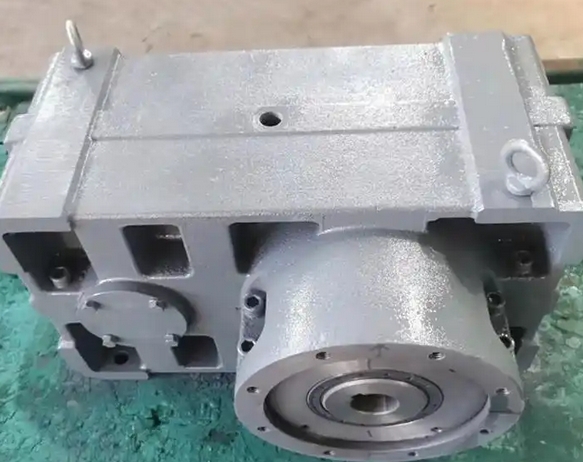

Cylindrical gear reducer ZSY200 hard tooth surface reducer for cement machinery with small volume

To ensure the levelness of the ZSY200 reducer foundation, the following methods can be referred to:Preparation before construction

Accurate measuring tools: Prepare high-precision level gauges, such as electronic level gauges, with an accuracy of up to 0.01mm/m, as well as long rulers, for measuring the flatness of large areas.

Reasonable design basis: Based on the size, weight, and operating force of the reducer, design the size and structure of the foundation. The foundation should have sufficient strength and stability to prevent settlement or deformation during the operation of the gearbox.

Basic construction process

Template installation: When installing the template, a level and plumb line should be used for calibration to ensure that the top surface levelness error of the template is within the allowable range, generally controlled within ± 2mm.

Concrete pouring: When pouring concrete, it is necessary to evenly distribute the material to avoid excessive accumulation on one side, which may cause the foundation surface to tilt. At the same time, use a vibrating rod to vibrate the concrete, ensuring that the concrete is dense and uniform, and preventing defects such as honeycombing and rough surfaces from affecting the levelness of the foundation.

Testing and adjustment after foundation construction

Leveling measurement: After the initial setting and before the final setting of the concrete, use a level to measure the surface of the foundation. Set measurement points at regular intervals (such as 1-2m) along the longitudinal and transverse directions of the foundation, measure and record the levelness data of each point.

Surface polishing: If it is found that the levelness of the foundation surface does not meet the requirements, polishing adjustments can be made before the concrete has fully solidified. For parts that exceed the horizontal requirements, use polishing tools to polish them; For low-lying areas, an appropriate amount of concrete can be added and plastered.

Secondary grouting: Before installing the reducer, use a spirit level again to check the levelness of the foundation. If the error exceeds the specified value, the method of secondary grouting can be used for adjustment. Apply a layer of grout evenly on the surface of the foundation, and ensure the levelness of the foundation by adjusting the thickness of the grout.

Throughout the entire process, construction personnel must strictly follow relevant specifications and standards for operation, conduct multiple measurements and calibrations to ensure that the levelness of the ZSY200 reducer foundation meets installation requirements.