Cycloid reducer motor XWD4-87-0.75kw installation method XWD3-87-1.1KW reducer

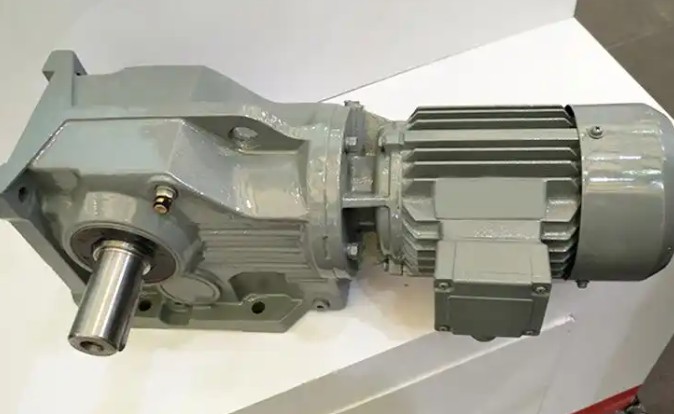

Cycloid reduction motor, as a common transmission equipment, plays a crucial role in the industrial field. Among them, the XWD series cycloidal reduction motor is widely favored by users for its high efficiency and stable performance. This article will provide a detailed introduction to the installation methods of the XWD4-87-0.75kw and XWD3-87-1.1KW reducers, and explore their advantages and precautions in practical applications.

1、 Overview of Cycloid Reduction Motor

Cycloid reduction motor is a transmission device that uses a cycloidal pinwheel reduction mechanism. Its working principle is to drive the three pairs of relatively symmetrical cycloidal gears on the cycloidal gear frame through the eccentric shaft on the input shaft, and the cycloidal gears on the arm bearings on the cycloidal gear frame to perform planar rotary motion. In the case where the input shaft and the cycloidal gear frame differ by one tooth, a series of periodically changing meshing points are formed between the tooth profile curve of the cycloidal gear of the rotating arm bearing on the cycloidal gear frame and the needle tooth profile curve on the needle gear frame, thereby achieving the deceleration effect. Cycloid reduction motors have the advantages of compact structure, high transmission ratio, smooth operation, low noise, and long service life. They are widely used in industries such as metallurgy, mining, petroleum, chemical, construction, lifting and transportation, textiles, papermaking, instruments, plastics, rubber, printing, and food.

2、 XWD4-87-0.75kw reducer installation method

1. Preparation work

Before installing the XWD4-87-0.75kw gearbox, it is necessary to ensure that the installation site is clean and free of debris, and to prepare the necessary tools and materials. At the same time, the appearance of the reducer should be checked for completeness, without any damage, rust, or other phenomena.

2. Install the base

Firstly, install the base of the reducer onto the pre prepared foundation. The installation of the base should ensure that it is level and stable, and the gap between it and the foundation should be even, and it should be fastened with bolts.

3. Install the motor

Install the motor on the input shaft of the gearbox, ensuring a reliable and secure connection between the motor and gearbox. At the same time, the position of the motor should be adjusted to align with the axis of the reducer, in order to avoid a decrease in transmission efficiency or damage to the equipment caused by improper installation.

4. Install the output shaft

Connect the output shaft of the reducer to the mechanical equipment being driven. During the connection process, it should be ensured that the output shaft is aligned with the axis of the mechanical equipment to avoid a decrease in transmission efficiency or damage to the equipment due to improper installation. At the same time, appropriate connectors (such as couplings) should be used to connect the output shaft to the mechanical equipment to ensure smooth and reliable transmission.

5. Debugging and operation

After installation, the gearbox should be debugged and tested for operation. During the debugging process, it is necessary to check whether each component is installed correctly and without looseness, and to check whether the transmission system runs smoothly and without abnormal noise. During the trial operation, the load should be gradually increased, and the operation and temperature changes of the gearbox should be observed to ensure its normal operation.

3、 XWD3-87-1.1KW reducer installation method

The installation method of XWD3-87-1.1kW reducer is similar to that of XWD4-87-0.75kw reducer, but the following points should be noted during the installation process: