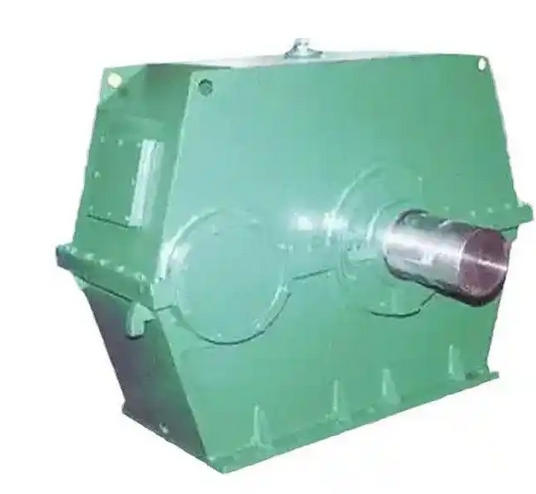

Method for reducing noise of ZQ1000-10.35-VI soft tooth surface horizontal reducer for general chemical machinery

The causes of noise in ZQ1000 gearbox are quite complex. Here are some methods to reduce its noise:Gear problem

Check gear wear: After long-term use, the gear teeth may experience wear, pitting, peeling, and other problems, which can lead to a decrease in gear meshing accuracy and generate noise. For gears with severe wear, they need to be replaced in a timely manner.

Ensure gear meshing accuracy: During installation, strictly adjust the gear meshing clearance and meshing marks according to the installation requirements. Excessive or insufficient meshing clearance can cause noise. Generally, the appropriate meshing clearance is ensured by adjusting the pre tension of the bearings, the axial position of the gears, etc.

Bearing issues

Check the wear of bearings: Bearing wear can cause shaft jumping and shaking, affecting the normal meshing of gears and generating noise. If bearing wear is found, it should be replaced with high-quality bearings of the same model in a timely manner.

Ensure the accuracy of bearing installation: When installing bearings, use appropriate installation tools to avoid damage to the shaft and ensure that the bearings are installed in place with appropriate pre tension.

Lubrication issues

Choose appropriate lubricating oil: Select lubricating oil with appropriate viscosity and good quality according to the working conditions and requirements of the reducer. Appropriate lubricating oil can reduce the friction between gears and bearings, and decrease the generation of noise.

Regularly replace lubricating oil: Lubricating oil will gradually deteriorate and its performance will decrease during use, so it needs to be replaced regularly. At the same time, when replacing the lubricating oil, it is necessary to thoroughly clean the inside of the gearbox to prevent impurities from entering.

Installation and foundation issues

Ensure installation level: When installing the reducer, it is necessary to ensure that the installation surface meets the requirements for levelness, otherwise it will cause uneven stress on the internal parts of the reducer and generate additional noise.

Tighten the connecting bolts: During installation, ensure that the reducer is firmly connected to the motor, working machine, etc. The connecting bolts should be tightened to prevent vibration and noise caused by looseness.

Setting up shock-absorbing foundation: Setting up a specialized shock-absorbing foundation for the gearbox, such as installing shock-absorbing pads or dampers between the foundation and the gearbox, can effectively reduce the transmission of gearbox vibration to the foundation, thereby reducing noise.

Other issues

Check the cleanliness inside the gearbox: Impurities and iron filings inside the gearbox can affect the normal operation of gears and bearings, producing noise. Therefore, during installation and use, attention should be paid to keeping the inside of the gearbox clean.

Optimize working environment: Try to avoid working the gearbox in harsh environments such as high temperature, humidity, and high dust, as these environmental factors may affect the performance of the gearbox and lead to increased noise.