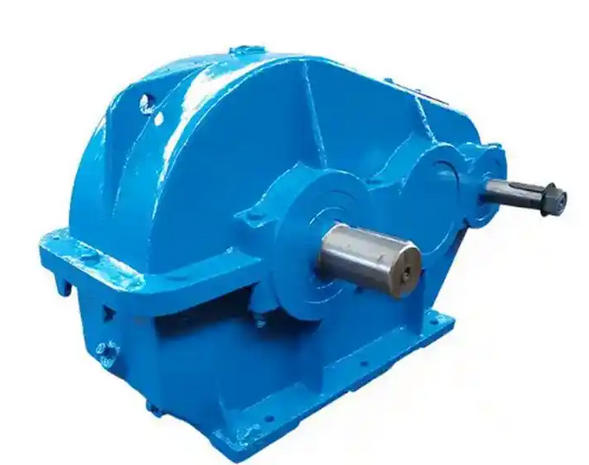

Comparison of specific data on the working efficiency of gear reducers made of different materials in high humidity environments

Regarding the comparison of the working efficiency of DCY series hard tooth surface gear reducers in high humidity environments, specific quantitative data (such as efficiency percentage differences) are not currently provided in publicly available materials. However, their performance can be analyzed through material characteristics and design differences1、 Comparison of core materials

Alloy steel carburizing and quenching gears (mainstream solution)

The tooth surface hardness reaches 58-62HRC, and high wear resistance is achieved by controlling the depth of the carburized layer (usually 0.8-1.2mm). It can still maintain stable transmission efficiency (theoretical efficiency ≥ 95%) in environments with humidity>80%.

The box is made of high-strength cast iron and equipped with a labyrinth seal, which can effectively block moisture from entering.

Tempered steel gear (medium hard tooth surface)

The tooth surface hardness is 300-350HBW, and its corrosion resistance is slightly inferior to that of carburized steel. In long-term high humidity environments, efficiency may decrease by about 3-5% due to corrosion.

Ordinary carbon steel gear (soft tooth surface)

Tooth surface hardness<300HBW, susceptible to moisture erosion, requires frequent maintenance, and efficiency fluctuations can reach 8-10%.

2、 Key influencing factors

Sealing technology: The DCY series adopts a double-layer oil seal and labyrinth seal, which can maintain the viscosity stability of lubricating oil and reduce friction loss in an environment with a humidity of 90%.

Surface treatment: The dense oxide layer of carburized and quenched gears can delay moisture corrosion, while quenched and tempered steel requires additional coating protection.

3、 Maintenance suggestions

In high humidity environments, the lubrication cycle should be shortened (recommended ≤ 2000 hours), and the water content of the oil should be monitored (<0.1%) to maintain efficiency.

Note: Specific efficiency data needs to be measured in conjunction with load, speed, and other operating conditions. It is recommended to refer to the environmental adaptability test report provided by the manufacturer.