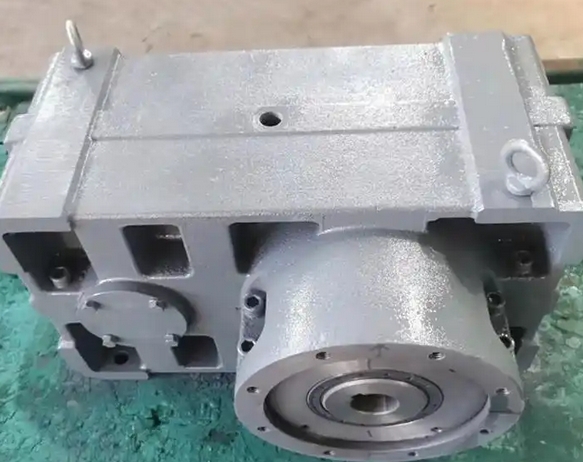

How to ensure the concentricity between the output shaft and the load shaft remains stable during the installation process of NRV030-60SZB8 worm gear reducer during long-term operation

To ensure the long-term stability of the concentricity between the output shaft and load shaft of NRV030-60SZB8 reducer, the core is to start from the installation foundation, connection method, fixing process, and maintenance monitoring, forming a full process guarantee.1. Strengthen the stability of the installation foundation

The foundation should be made of cast iron, thick steel plate or concrete material, with sufficient rigidity and flatness ≤ 0.1mm/m to avoid deformation during operation.

A complete steel adjustment pad should be placed between the reducer foot and the foundation, with no more than 3 layers of pads, and should be fully attached to the foot.

The basic surface needs to be treated with rust prevention, and additional waterproof structures should be added during outdoor installation to prevent accuracy deviation caused by foundation corrosion.

2. Choose reliable connection and positioning methods

Priority should be given to using elastic couplings (such as plum blossom couplings), which can compensate for small deviations and reduce the impact of vibration on concentricity.

If a rigid connection is used, positioning pins need to be installed at the flange to ensure precise fit of the connection surface without any misalignment gaps.

The fit between the shaft and the coupling adopts a transitional fit (such as H7/k6) to avoid interference or excessive clearance that may cause loosening after long-term operation.

3. Strengthen the fixing and locking process

The anchor bolts should be of high-strength grade (≥ 8.8 grade), with specifications matching the reducer foot holes (usually M8 or M10), and tightened step by step in diagonal order to the specified torque.

Install anti loosening washers (such as spring washers and anti loosening nuts) on the bolt head to prevent vibration from causing the bolt to loosen.

The coupling bolts also adopt anti loosening design, and the tightening torque is consistent to prevent deviation caused by uneven force.

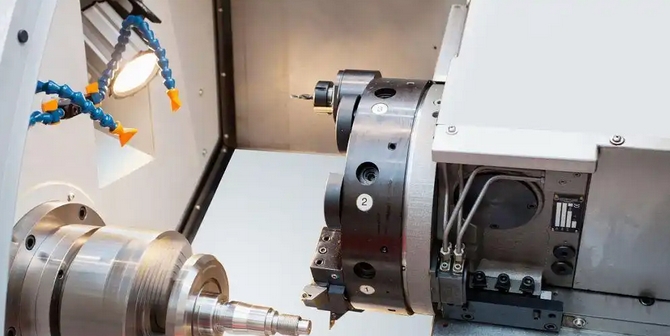

4. Strictly control the concentricity accuracy during installation

After installation, use a dial gauge to check for radial deviation ≤ 0.05mm and angular deviation ≤ 0.03mm/m, with a safety margin reserved above the conventional standard.

Before operation, conduct a no-load test run (30 minutes). After shutdown, recheck the concentricity and confirm that there is no deviation rebound before loading and running.

In multi axis linkage scenarios, the load shaft position is uniformly adjusted based on the output shaft of the gearbox to avoid cumulative errors.

5. Regular maintenance and monitoring

Stop the machine every 3-6 months to check the fastening status of the foundation bolts and coupling bolts, and promptly tighten any loose bolts.

Recheck the concentricity once a year. If the deviation exceeds the allowable range, correct it by adjusting the gasket or coupling position.

Regularly replace lubricating oil (according to the manufacturer's required cycle) to avoid poor lubrication causing increased vibration and affecting concentricity stability.