What are the performance advantages of MBY560-7.1 hard tooth gear reducer

The MBY560-7.1 hard tooth gear reducer has the following performance advantages:High bearing capacity: The gear material is made of high-quality alloy steel, which has been treated with carburizing and quenching technology. The tooth surface hardness is high, and the working condition coefficient is selected as 1.75, which makes the gear have a high bearing capacity and can withstand high input power, high output torque, and impact loads. It is suitable for harsh working conditions in industries such as cement and coal.

High gear accuracy: The gear accuracy shall not be lower than the level 6 accuracy requirement in ISO1328-1995. The CNC gear grinding process is adopted to effectively ensure the accuracy indicators such as tooth profile and tooth direction of the gear, thereby making the gear meshing more accurate and the transmission smoother.

High transmission efficiency: Adopting a single-stage reduction design, the gear mesh clearance is reasonable, and after modification, the comprehensive transmission efficiency of each gear stage can reach 0.98, with less energy loss in the power transmission process, which can effectively improve the overall working efficiency of mechanical equipment.

Long service life: Designed with high reliability and a durable lifespan, all rolling bearings have a lifespan of over 100000 hours. At the same time, the gears have good wear resistance and can maintain good working conditions during long-term operation, reducing the frequency of maintenance and replacement.

Smooth operation and low noise: The design of helical gears greatly increases the contact area between gears, and the gear accuracy is high, which can maintain higher stability during operation, reduce vibration and noise, and is suitable for occasions with strict noise requirements.

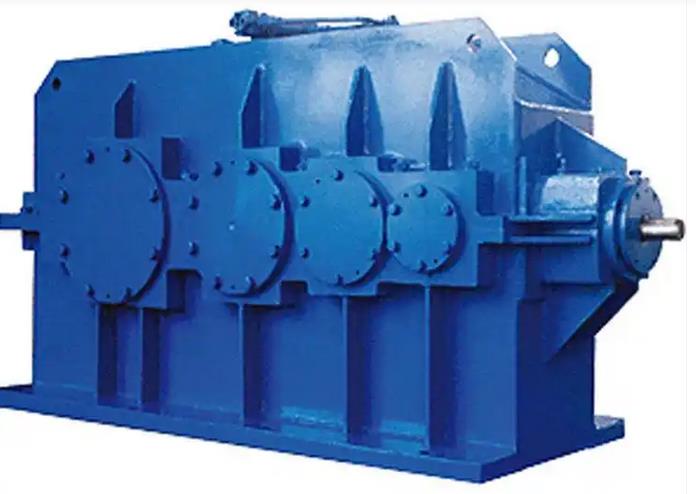

Compact structure and easy installation: It has the characteristics of small size and light weight, simple and elegant appearance, low installation space requirements, and diverse installation methods. Suitable installation methods can be selected according to actual working conditions, and it is also convenient for technical transformation and equipment upgrading of old factories.

Reliable lubrication: The gears and bearings adopt forced lubrication and are equipped with dedicated oil stations, which can be connected with standard oil station products, providing good lubrication and cooling for the gears and bearings, ensuring the normal operation and service life of the reducer.