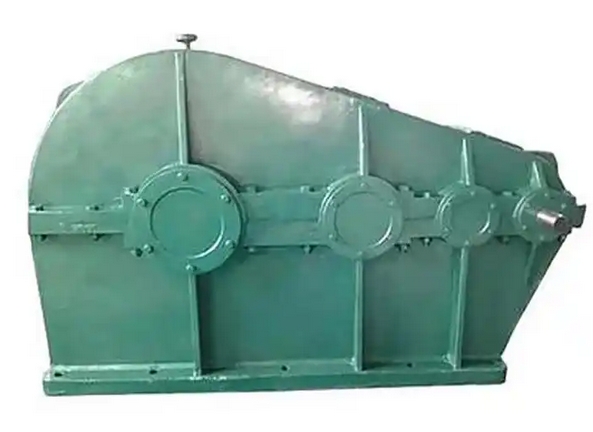

What materials can be used for welding NGW-L-F31-4.43-11KW reducer base

NGW-L-F31-4.43-11KW belongs to the NGW series planetary gearbox, and its base is preferably made of cast iron. Low carbon steel or low-alloy high-strength steel welding parts are also commonly used, and corresponding welding materials need to be matched. The specific material selection is as follows:1. Base material (machine base body material)

HT300 gray cast iron: This is a commonly used base material for NGW series reducer bases. The material has high strength, good wear resistance, and can withstand the vibration and load during equipment operation, suitable for support requirements under 11KW power conditions. If there are cracks, sand holes or other defects in the machine base during welding repair, cast iron special welding rods should be used.

Q235A/Q235B low carbon steel: As a commonly used base material for welding structures, it has excellent welding performance and low cost. It is suitable for making machine base welding parts and can meet the basic bearing requirements of this type of reducer. It is widely used for welding the cover plate, rib plate and other components of the reducer machine base, and is suitable for mass production scenarios.

Q345B low-alloy high-strength steel: Compared with Q235 series, it has better strength and toughness. If the reducer is used in working conditions with high vibration or high rigidity requirements for the machine base, using this material can improve the overall stability of the machine base. However, attention should be paid to controlling heat input during welding to avoid affecting material performance.

2. Welding material (corresponding to the welding material of the base material)

Suitable welding material for cast iron base material: If the machine base is HT300 gray cast iron, priority should be given to Z308 pure nickel welding core electrode, which has good crack resistance and machinability, and is suitable for welding important cast iron parts such as machine bases; If pursuing higher strength, Z408 nickel iron welding core electrode can be used, which has better crack resistance than Z308 for ductile iron welding and is also suitable for cast iron parts with higher phosphorus content; For repairing small defects in non stress areas, Z508 nickel copper core welding rod can be used, which has a relatively low cost, but attention should be paid to preheating to avoid cracks.

Low carbon steel/low alloy steel base material compatible welding material: When welding Q235 series low carbon steel, J422 (E4303) welding rod is commonly used, which is universal for both AC and DC, has a simple welding process, and can meet the strength requirements of machine base welding; If gas shielded welding is used, ER49-1 welding wire can be selected, suitable for Q235 and Q345 series steel, with high welding efficiency and good weld formation; When welding Q345B low-alloy steel, low hydrogen E5015 welding rods can be used to reduce the risk of cold cracking and adapt to working conditions with high weld quality requirements.