Application and installation process of planetary gearbox in automated production line

Planetary reducers play a crucial role in automated production lines. It provides strong support for the efficient and precise operation of production lines with its unique performance advantages. As a professional manufacturer specializing in the design and production of planetary gearboxes, we have over 20 years of experience in custom design and production of planetary gearboxes. Next, let's learn about the application and installation process of planetary gearboxes on automated production lines.

On automated production lines, planetary reducers are mainly used in the following areas:

Firstly, drive various conveying devices. In automated production lines, it is necessary to accurately and smoothly transport raw materials, semi-finished products, and finished products. Planetary reducers can ensure the stable operation of the conveying equipment and meet the requirements of different speeds and loads.

Secondly, it plays a crucial role at the joints of the robot. Make the robot's movements more flexible and precise, improve the robot's work efficiency and accuracy, and adapt to complex production tasks.

Furthermore, it is applied to various processing equipment. Assist in adjusting processing speed and force to ensure consistency and stability of processing quality.

Below is a detailed introduction to the installation process of planetary gearboxes on automated production lines:

Step 1: Preparation before installation. Carefully inspect the appearance of the reducer to ensure it is intact and undamaged, and verify whether the model and parameters match the design requirements. Meanwhile, prepare the necessary installation tools and fixing bolts.

Step 2: Determine the installation location. According to the layout and design requirements of the automated production line, select a suitable installation location to ensure that the reducer can cooperate well with other equipment and facilitate subsequent maintenance and repair.

Step 3: Secure the gearbox. Use appropriate bolts to firmly fix the planetary gearbox on the installation foundation, paying attention to tightening the bolts according to the specified torque to prevent the gearbox from loosening during operation.

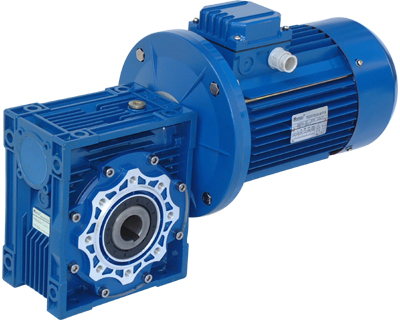

Step 4: Connect the input shaft and output shaft. According to specific transmission requirements, connect the input shaft to the power source (such as a motor) and the output shaft to the driven equipment. During the connection process, it is important to ensure the concentricity and alignment of the shaft to avoid transmission issues or malfunctions caused by improper installation.

Step 5: Adjust the position and angle of the reducer. By fine-tuning the position and angle of the gearbox to achieve optimal coordination with surrounding equipment, the accuracy and stability of the transmission are ensured.

Step 6: Check the lubrication system. Ensure sufficient lubricating oil in the gearbox and unobstructed lubrication pipelines to ensure good lubrication of the gearbox during operation.

Step 7: Conduct a trial run. After installation, conduct a no-load trial run to check if the gearbox runs smoothly and without abnormal noise, and if all components are working properly. If everything is normal, gradually load for trial operation and observe the performance of the gearbox under different loads.

Step 8: Final debugging and optimization. Based on the results of the trial operation, necessary adjustments and optimizations should be made to the parameters of the reducer, such as adjusting the transmission ratio, adjusting the lubrication amount, etc., to achieve the best operating effect.