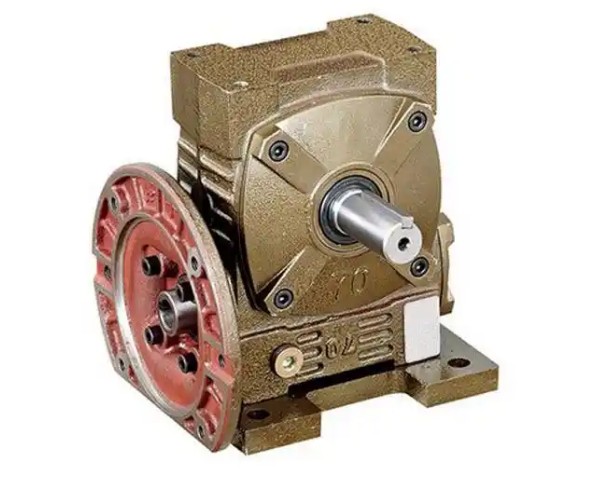

What are the effects of unreasonable material matching on the worm gear of WPWDA175-60-7.5KW reducer

The material matching of the worm gear of WPWDA175-60-7.5KW reducer (the worm gear is usually made of tin bronze/aluminum bronze, and the worm gear is made of alloy structural steel that has undergone nitriding treatment) is unreasonable, which will directly damage the frictional balance of the meshing surface and cause multidimensional failure problems. The following are 8 core effects (in order of hazard level):

Accelerated wear of tooth surface: If the purity of the copper alloy of the worm gear is insufficient (including impurities) or the surface hardness of the worm gear is not up to standard (without nitriding treatment, hardness<HRC58), the shear and compression resistance of the tooth surface is insufficient during meshing, which is prone to abrasive wear and adhesive wear, and the service life is shortened by more than 50% compared to normal working conditions.

Fatigue peeling of tooth surface: If the copper alloy grains of the worm gear are coarse and the toughness of the worm material is insufficient, the contact stress of the tooth surface will repeatedly act during long-term meshing, resulting in early pitting and cracking, which will then develop into large-scale peeling, affecting the transmission accuracy.

Significant decrease in transmission efficiency: Improper material matching leading to increased frictional resistance can reduce the efficiency of the gearbox by 8% -15% (normal efficiency of 85% -90%), accompanied by an increase in motor current and energy consumption.

Tooth surface corrosion damage: If the lead content of the copper alloy of the worm gear exceeds the standard, or if the rust prevention treatment of the worm gear surface is improper, when combined with lubricating oil containing sulfur and phosphorus extreme pressure agents, chemical corrosion is prone to occur, resulting in spots and pits on the tooth surface, further reducing the wear resistance.

Shortened maintenance cycle: Due to frequent issues such as wear and corrosion, it is necessary to replace worm gear components and lubricating oil frequently, which increases maintenance costs by 30% -60%. At the same time, equipment downtime is prolonged, affecting production continuity.