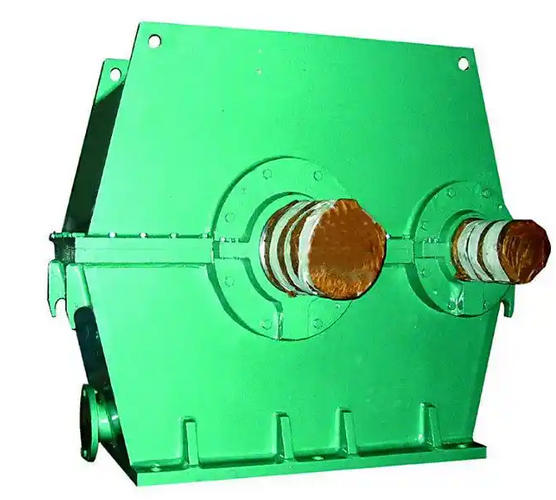

How to maintain and upkeep TY63-31.5-5.5 coaxial reducer cylindrical gear hard tooth surface reducer

Maintaining and upkeep the TY63 gearbox is crucial for extending its service life and ensuring normal equipment operation. The following are some specific maintenance measures:

Daily inspection

Appearance inspection: Regularly check whether there are cracks, damages, or deformations in the casing of the reducer, and whether the bolts at each connecting part are loose. If there is any looseness, it should be tightened in a timely manner to prevent component damage or oil leakage caused by looseness.

Oil level inspection: Observe the oil level through the oil level gauge to ensure that the oil level is within the normal range. Low oil level can cause poor lubrication, accelerate gear and bearing wear; If the oil level is too high, it may cause problems such as oil temperature rise and oil leakage.

Oil temperature inspection: During operation, measure the oil temperature of the reducer with a thermometer. The normal operating oil temperature should be between -40 ℃ and 40 ℃. If the oil temperature is too high, it may be caused by excessive load, poor lubrication, or poor heat dissipation. It is necessary to promptly troubleshoot the problem.

Noise and vibration inspection: Monitor the sound of the gearbox during operation. Under normal circumstances, it should run smoothly with low noise. If there is abnormal noise, vibration or impact, it may be due to gear wear, bearing damage or other component failure, and the machine should be stopped immediately for inspection.

regular maintenance

Lubricating oil replacement: After running for 300-500 hours, the new gearbox should undergo the first oil change, and then the lubricating oil should be replaced every 2000-3000 hours or every six months to one year thereafter. When replacing, it should be done after the gearbox has stopped and cooled down. First, drain the old oil, rinse the inside of the gearbox with clean oil, and then add an appropriate amount of new lubricating oil.

Filter cleaning or replacement: The lubricating oil filter of the gearbox should be cleaned or replaced regularly, usually checked every 1000-1500 hours of operation. If the filter is clogged, it will affect the flow of lubricating oil and lead to a decrease in lubrication effect.

Gear and bearing inspection: Regularly open the inspection cover of the reducer to check the wear of the gears, such as whether there is wear, pitting, bonding and other phenomena on the tooth surface. Measure the tooth thickness of the gears to determine whether it exceeds the wear limit. At the same time, check the clearance and wear of the bearings, and replace them promptly if there are any abnormalities.

Sealing component inspection and replacement: Check whether the oil seals, sealing rings, and other sealing components of the gearbox are aging, damaged, or leaking. If there is any leakage, replace the sealing components in a timely manner to prevent lubricating oil leakage and affect the normal operation of the gearbox.

Other precautions

Load control: To avoid long-term operation of the gearbox under overload or impact loads, strictly select the appropriate load according to the rated power and torque of the gearbox to extend its service life.

Cleaning and Protection: Keep the surface of the reducer clean, promptly remove dust, oil stains, and debris to prevent their accumulation from affecting heat dissipation. At the same time, appropriate protection should be provided for the gearbox to prevent it from being damaged by external collisions, corrosion, and other factors.