Common problems in the application of K series reduction motors

With the rapid development of industrial enterprises and the continuous progress of the gear reducer industry, the application scope of K-series reduction motors in medical equipment, aerospace enterprises, transportation and other industries is becoming more and more extensive, and has become an indispensable part of current social development. The K series reduction motor generally plays a role in low-speed and high torque transmission equipment, achieving the required reduction effect of the equipment by utilizing the speed of the motor and the transmission ratio of the gears. This article starts with the common problems in the development of K series reduction motors, and puts forward opinions and suggestions on who is better to apply gear reducers in enterprises.

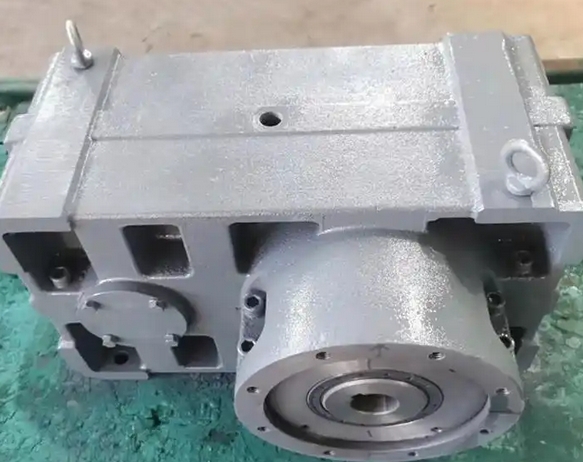

As a type of transmission device, the K series reduction motor is prone to increasing wear and tear between its components over time, which directly affects the overall operational efficiency of the equipment. The common components of bevel gear reducers mainly include gears, bearings, fasteners, and seals. Their common faults mainly include sliding friction between gears, friction loss between bearings, and problems caused by lubricating oil leakage. The common problems are summarized as follows:

There are two main situations regarding the issue of heating: firstly, the bevel gear reducer motor has a severe fever, but there is no problem with the sound. Generally speaking, it is a problem of too much oil. If there is friction sound from metal parts while the fever is occurring, it can be basically determined as a lack of oil problem; If there is a noticeable abnormal noise during the operation of the equipment and the sound becomes heavy, corresponding to an increase in load current, it indicates that the bevel gear reducer has been overloaded and should be stopped immediately to investigate the cause and reduce the operating load of the machine. It should be noted that during the use of engine oil, attention should be paid to the height of the oil surface, and the height should be kept within the specified range. In the absence of a dipstick, the oil surface height should be kept between the three tooth heights of the large gear and one-third of the diameter of the large gear, and should not be too high or too low. Tooth surface problems: Tooth surface problems are common in K series reduction motors, mainly including tooth clearance wear, poor meshing between new and old gears, and tooth surface pitting. Gear clearance wear is often manifested as knocking sound when the K series reduction motor is empty, and the sound becomes smaller under load without knocking noise. At this time, the gear with higher wear should be replaced, or the worn gear should be turned over for use under tight time. After the gear is just replaced, there are often problems such as loud and uneven sound, especially when the new and old gears are in use. This is because the tooth surfaces of the new and old gears have not fully contacted. After a period of use, the machine's sound will return to normal. In the case of accidentally entering foreign objects in the umbrella gear reduction machine, if there is uneven sound, the cause should be immediately checked and dealt with in a timely manner to avoid affecting the use of the machine; The latter is the problem of pitting corrosion on the tooth surface, which is mainly characterized by the loud "rumbling" sound produced by the bevel gear reducer during operation. At this time, the machine should be stopped immediately and it should be determined in a timely manner whether it is machine overload, high oil level, or severe wear on the tooth surface. Corresponding solutions should be taken for different situations.