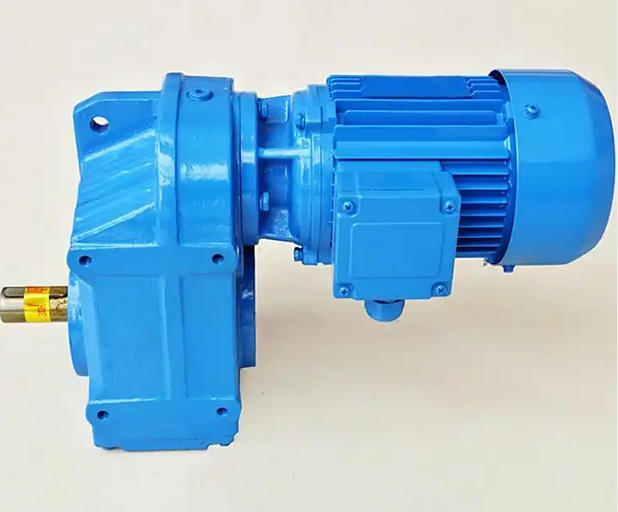

What are the precautions for installing F67-66.13-2.2KW reducer bearings

The following are key precautions for the installation of F67-66.13-2.2KW reducer bearings, combined with installation specifications and common problems for comprehensive explanation:1、 Preparation before installation

Cleaning and Inspection

Clean the bearings and shaft necks with refined kerosene to ensure no metal debris residue, and only wipe the surface of the sealed bearings with rust proof oil.

Check the diameter deviation of the shaft neck (≤ 0.01mm) and the roundness error of the bearing seat (≤ 0.02mm). If they exceed the tolerance, they need to be repaired.

Lubrication treatment

Open type bearings need to be filled with lubricating grease (occupying 1/3-1/2 of the bearing chamber), while sealed bearings can be installed directly.

2、 Installation process control

Force application method

When the inner ring is interference fit, use a copper rod to strike the inner ring (non rolling element), or use hydraulic pressing method (pressure gradient ≤ 2mm/s).

The hot charging method requires oil bath heating to 80-100 ℃, and the temperature of the sealed bearing should be ≤ 80 ℃.

Axial positioning

The bearing should be tightly attached to the shaft shoulder, and after cooling, manual rotation should be flexible without jamming, and the axial clearance should meet the design requirements.

3、 Verification after installation

1. Run test

Run without load for 30 minutes, bearing temperature rise ≤ 25 ℃, rolling bearing temperature limit 80 ℃.

Use a dial gauge to detect axial runout (allowable value ≤ 0.02mm).

2. Sealing inspection

Apply soapy water to the joint surface, and let in 0.2MPa compressed air to maintain pressure for 15 minutes without any leakage.

4、 Common problem prevention

Overload risk: Avoid excessive preload force causing deformation of the raceway.

Lubrication failure: Regularly check the condition of the lubricating grease, and the variable frequency motor needs to prevent shaft current corrosion.