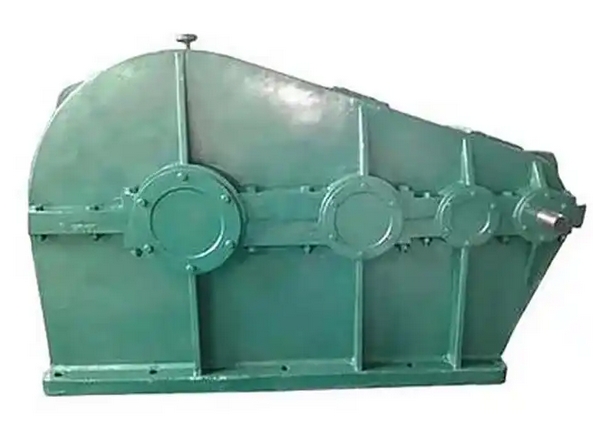

What are the advantages and disadvantages of ZS85-160-III soft tooth surface gear reducer

The advantages of ZS85-160-III soft tooth surface gear reducer include smooth transmission, strong adaptability, and low manufacturing and maintenance costs. The main disadvantages are limited load-bearing capacity and short service life, as follows:advantage:

Smooth transmission and low noise: Soft tooth surface reducers usually use involute helical cylindrical gear transmission, which makes the gear meshing process smoother, with less impact and vibration, resulting in lower noise during operation. It can be applied to situations with higher noise requirements.

Has certain impact resistance: Soft tooth surface gears are usually made of medium carbon alloy steel and subjected to quenching and tempering treatment, balancing material toughness and surface machinability. When subjected to impact loads, the small plastic deformation on the surface can absorb energy, avoid crack propagation, and adapt to some working conditions with vibration and impact loads.

Good load adaptability: Its structural design enables it to withstand a certain range of loads, with good lubrication and reduced wear. It can still operate stably under special working conditions such as high load and low speed, and can adapt to various working scenarios. It is widely used in industries such as metallurgy, mining, and chemical engineering.

The manufacturing process is simple and the cost is low: Soft tooth surface reducers generally use ordinary steel without complex heat treatment or precision that does not meet the requirements of hard tooth surfaces. The production cycle is short, and the manufacturing cost is relatively low, so the market price is more affordable. For enterprises or equipment with limited budgets, it is not suitable

Wrong choice.

Easy maintenance and repair: Soft tooth surface reducers often use simple lubrication methods, such as grease lubrication, without the need for complex cooling measures, making daily maintenance more convenient. Its structural design is also easy to disassemble, inspect, and install. When a malfunction occurs, maintenance personnel can easily carry out maintenance and component replacement.

Disadvantages:

Relatively low load-bearing capacity: Compared with hard tooth surface reducers, soft tooth surface reducers have lower gear hardness and limited maximum load capacity, making them unsuitable for heavy load and high torque working environments. Otherwise, gear wear, deformation, and other problems may occur, affecting the normal operation and service life of the reducer.

Low transmission efficiency: Due to the material and manufacturing process characteristics of soft tooth surface gears, energy loss is relatively large during the transmission process, and the transmission efficiency is generally lower than that of hard tooth surface reducers, which may lead to certain energy waste and increase operating costs over long-term use.

Short service life: In high load, frequent start stop, or harsh working environments, soft tooth surface gears are more prone to wear, pitting, and other forms of failure, which can shorten the overall service life of the gearbox and require more frequent maintenance and component replacement, increasing maintenance costs and downtime.

High requirements for the working environment: Soft tooth surface reducers have relatively poor adaptability to the working environment and are not suitable for long-term operation under extreme conditions such as high temperature, high humidity, and high dust. Otherwise, it will accelerate the wear and corrosion of the gears, affecting their performance and service life.