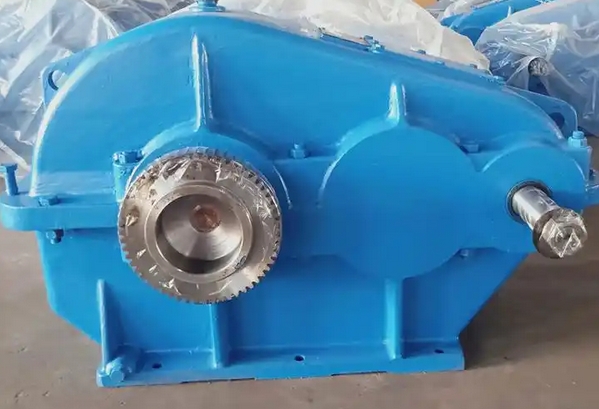

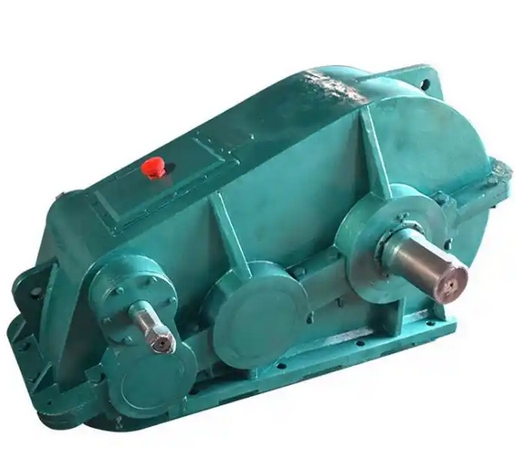

Introduce the working principle of the sealing structure of ZQA250-31.5-1 reducer

The common sealing structure and working principle of ZQA250-31.5-1 reducer are as follows:Mechanical seal:

Composition and principle: Mechanical seal, also known as end face seal, is usually composed of a moving ring, a stationary ring, a clamping element, and a sealing element. The moving ring rotates together with the shaft, and the moving ring and the stationary ring are tightly fitted to form a sealing surface. The dynamic ring relies on the pressure of the liquid in the sealed chamber to press its end face against the static ring end face, and generate an appropriate pressure ratio and maintain a very thin liquid film on both ring end faces to prevent medium leakage.

Function: The pressure generated by compressing the components can keep the end face of the reducer in contact even when not in operation, ensuring that the sealing medium does not leak out and preventing impurities from entering the sealing end face. The sealing element plays a role in sealing the gap between the dynamic ring and the shaft, and the gap between the static ring and the cover. At the same time, the elastic element has a buffering effect on the vibration and impact of the reducer.

Oil seal sealing:

Principle: There is an oil film controlled by the edge of the oil seal between the oil seal and the shaft, which has fluid lubrication characteristics. Under the action of liquid surface tension, the stiffness of the oil film precisely forms a crescent surface at the contact end between the oil film and air, preventing leakage of the working medium and achieving sealing of the rotating shaft.

Influencing factors: The sealing ability of the oil seal depends on the thickness of the oil film on the sealing surface. If the thickness is too large, the oil seal will leak; If the thickness is too small, dry friction may occur, causing wear on the oil seal and shaft; If there is no oil film between the sealing lip and the shaft, it is easy to cause heating and wear.

Maze seal:

Structure and principle: Maze seal is composed of a tortuous channel formed between rotating and stationary components. When the gearbox is running, the internal lubricating oil or gas passing through the labyrinth channel is obstructed by the tortuosity of the channel, forming resistance and reducing leakage. At the same time, the labyrinth seal can also utilize the centrifugal force to throw the lubricating oil that may leak back into the reducer.

Advantages: The labyrinth seal does not require direct contact with the rotating shaft, so it will not cause wear and can adapt to higher speeds and temperatures, effectively blocking lubricating oil leakage and external impurities from entering.