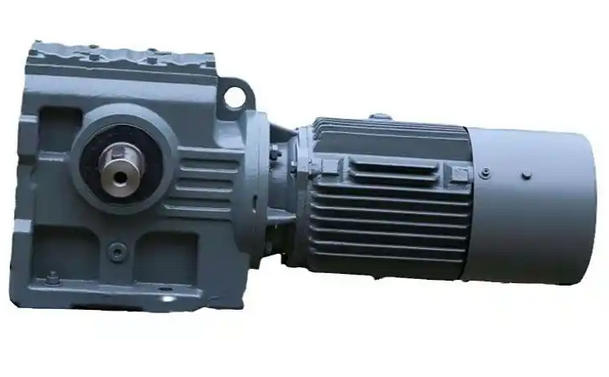

What other gear grinding techniques can be used for B2SH4 gearbox gear machining besides the gear grinding method

On the premise of not using the gear grinding method, the gear of B2SH4 reducer is more suitable to use the "forming method" for gear grinding, and secondly, "strong honing" can be considered; When batch and rhythm allow, "hard tooth surface scraping/hard rolling" can also be evaluated as an alternative to rough grinding.Optional 'non evolving' processes

Forming method for gear grinding (forming grinding wheel for gear grinding)

Key points: Use numerical control to trim the grinding wheel into the target tooth shape and grind it directly; Good efficiency and accuracy, suitable for batch hard tooth surface precision machining, easy to achieve tooth profile/tooth direction modification.

Adaptability: Suitable for B2SH4 medium/small module cylindrical gears and planetary gear systems, with a stable accuracy of 6 to 4 levels.

Strong gear honing

Key points: The gear shaped honing wheel meshes with the workpiece in a staggered manner, using relative sliding to achieve hard tooth surface finishing and micro correction, with fast pace and low cost.

Adaptability: To reduce noise and improve surface integrity of ground or shaved teeth, suitable for mass production.

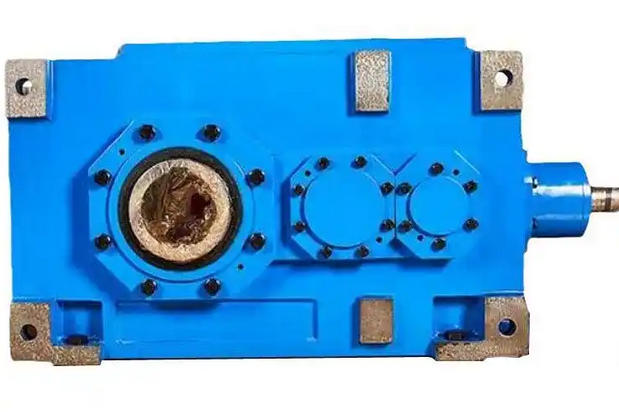

Hard tooth surface scraping/hard rolling (hard tooth surface rolling)

Key point: Directly machining hardened tooth surfaces with CBN coated rolling cutters, replacing rough grinding, significantly improves efficiency compared to traditional grinding.

Adaptability: Used for rough or semi precision machining, requiring subsequent finishing (forming grinding or strong honing) to achieve final accuracy.