What is the specific definition of constant load and medium impact load of ZFY180-280-II reducer?

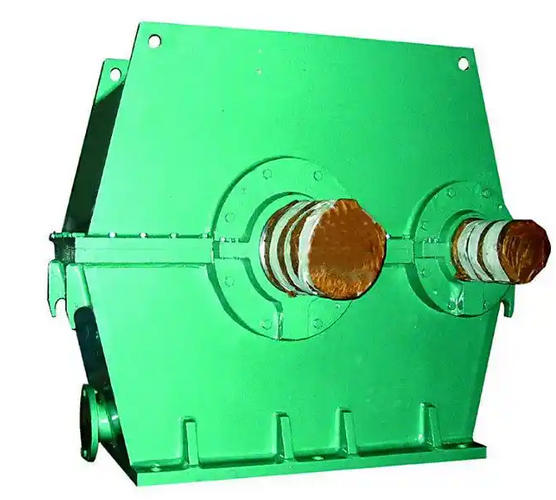

ZFY180-280-II is a hard toothed cylindrical gear reducer with a base size of 180 and a transmission ratio of 280. It is suitable for small and medium-sized motors and is commonly used in light industry, building materials, transportation and other fields. Constant load and moderate impact load are the core classifications for adapting the load characteristics of this gearbox. The specific definitions and characteristics are as follows:1、 Constant load

Constant load refers to the most ideal operating condition for the gearbox during operation, where the load torque is stable without fluctuations or with minimal fluctuations, and there is no impact load.

1. Core quantitative indicators

The actual working torque fluctuation range is ≤± 5%, and it remains stable in the range of 70%~95% of the rated torque for a long time;

Peak torque ≤ 1.1 times the rated torque, and there is no instantaneous peak impact;

Corresponding operating condition coefficient K=1.0-1.1.

2. Typical features

The load is continuous and stable, the gear meshing is uniformly stressed, and the radial/axial load borne by the bearing has no sudden changes;

The equipment operates at a constant speed without frequent start stop or forward/reverse operations, and the start stop interval is usually ≥ 30 minutes.

3. Typical operating conditions for adaptation

Uniform speed precision conveying equipment: such as belt conveyors for automated production lines, electronic component sorting conveyors;

Constant torque and constant speed equipment: such as transmission systems for small constant pressure water pumps, fans, and metering pumps;

Low speed smooth mixing equipment: such as mixing mechanisms for liquid batching tanks and lubricating oil blending tanks.

2、 Moderate impact load

Medium impact load refers to the regular or random fluctuation of the load torque during the operation of the gearbox, accompanied by obvious instantaneous impact. The peak load is higher than the constant load, but has not reached the level of strong impact.

1. Core quantitative indicators

The actual working torque fluctuation range is between ± 30% and ± 50%;

The peak torque is 1.5-2.0 times the rated torque, with a moderate impact frequency (10-30 times per hour) and an impact duration of seconds;

Corresponding operating condition coefficient K=1.5-2.0.

2. Typical features

The load has periodic or random impacts, and the gears will bear instantaneous additional loads during meshing, making the bearings prone to fatigue damage;

The equipment may have frequent start stop and forward/reverse operations, or there may be material impact or equipment jamming at the load end;

Under long-term operation, the gearbox is prone to problems such as increased vibration, accelerated tooth wear, and high bearing temperature rise.

3. Typical operating conditions for adaptation

Material conveying equipment: such as scraper conveyor (conveying block materials), bucket elevator (uneven feeding);

Mixing equipment: such as mortar mixer, feed mixer (materials with clumping);

Light industry forming equipment: such as transmission mechanisms for small brick making machines and ceramic body presses.