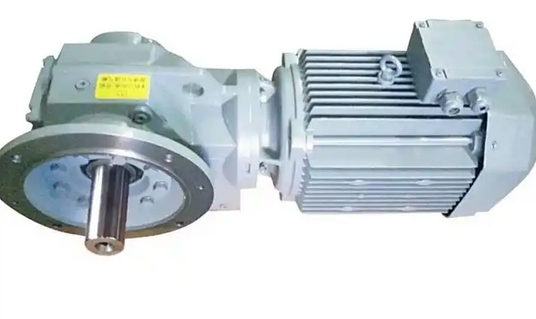

What high-temperature protective measures are taken for the TKF48-MY90S4/BMG/HF-39.61-M5-A reducer

To analyze the high temperature protection measures of TKF48-MY90S4/BMG/HF-39.61-M5-A gear reducer, it is necessary to combine its model structure (gear transmission, motor adaptation, installation form, etc.) and the general high temperature protection logic of industrial reducers, and develop from three core dimensions: "active prevention of high temperature generation", "passive strengthening of heat resistance", and "real-time monitoring and emergency protection". The specific measures and adaptability are as follows:1、 Proactive prevention: reduce the source of high temperature and optimize heat dissipation efficiency

Active protection is the core, which reduces internal heat generation and improves heat dissipation efficiency to prevent high temperature accumulation from the root. Specific measures to adapt to this type of gearbox include:

1. Optimization of lubrication system (core protection)

More than 60% of the high temperature of gear reducers comes from gear/bearing friction, and the lubrication system is a key protective link. This model requires targeted configuration:

High temperature special lubricant: Choose synthetic gear oil with viscosity index ≥ 140 and flash point ≥ 220 ℃ (such as poly - α - olefin PAO type and ester synthetic oil) to replace ordinary mineral oil - it can withstand working conditions of 120-150 ℃ (ordinary mineral oil is only 80-100 ℃), and is not easily oxidized or deteriorated at high temperatures, maintaining the strength of the lubricating film and reducing frictional heat generation.

Forced lubrication/circulating cooling: If the operating temperature is greater than 120 ℃, an additional lubricating oil circulating cooling system (such as an external oil pump+air-cooled/water-cooled heat exchanger) can be configured to continuously remove the heat from the lubricating oil and control the oil temperature within a safe range of 80-100 ℃ (the "BMG" label of this model may include bearing seal optimization, adapted to the sealing and leak prevention requirements of circulating lubrication).

Regular lubrication maintenance: Replace the lubricating oil every 2000-3000 hours according to the operating conditions (shorten the cycle by 30% under high temperature conditions), and clean the oil gauge and oil filter to avoid impurities blocking the oil circuit and causing local overheating (this model "HF" may be associated with "high-efficiency filtration" design, and the filter element status needs to be checked regularly).

2. Strengthen the heat dissipation structure

By optimizing the body design to accelerate heat dissipation, structural improvements adapted to this model include:

Heat sink encryption/expansion: Add high-density heat sinks (thickness 3-5mm, spacing 10-15mm) on the outside of the gearbox body, or install aluminum heat dissipation fan covers on the motor end cover (MY90S4 motor, 90 machine base size) to improve natural convection heat dissipation efficiency, especially suitable for low to medium load high temperature scenarios without forced cooling (such as ambient temperature 50-60 ℃).

Ventilation environment optimization: Ensure that a ventilation space of ≥ 300mm is reserved around the reducer during installation, avoiding proximity to heat sources such as boilers and heating furnaces; If it is a closed cabinet, an axial flow fan or a heat dissipation skylight should be installed to forcibly replace the hot air inside the cabinet and prevent local environmental temperature accumulation from causing overheating of the machine body.

2、 Passive reinforcement: Improve the heat resistance of components and resist high-temperature damage

When high temperatures are inevitable in the environment, upgrading the material and structure of core components can enhance the high-temperature resistance of the gearbox. The specific measures are as follows:

1. Core component material upgrade

Gears and bearings: Materials with stronger high-temperature toughness are used, such as 20CrMnTi carburizing and quenching (surface hardness HRC58-62, unchanged wear resistance at high temperatures) for gears, and high-temperature resistant bearing steel (such as SUJ2+special heat treatment) for bearings, which can withstand short-term high temperatures of 150-200 ℃, avoiding tooth surface wear or bearing jamming caused by material softening.

Seals: Replace ordinary nitrile rubber (NBR) seals with fluororubber (FKM) or perfluoroether rubber (FFKM) seals - fluororubber can withstand long-term high temperatures of 200 ℃, while perfluoroether can withstand extreme high temperatures of 300 ℃, effectively preventing seal aging and oil leakage under high temperatures (this model "M5" is an installation form, and it is necessary to ensure that the seal is compatible with the installation interface).

Box and motor: The box is made of HT250 gray cast iron (with low deformation rate at high temperatures), and the motor (MY90S4) is made of Class H insulation material (with a temperature resistance of 180 ℃, higher than the 130 ℃ of ordinary Class B) to avoid insulation breakdown and burnout of the motor winding caused by high temperatures.

2. Structural heat protection design

Thermal insulation barrier: If the reducer needs to be close to high-temperature equipment (such as metallurgical production lines), a high-temperature resistant insulation board (such as ceramic fiber board, stainless steel insulation cover) can be installed between the two to reduce radiative heat transfer and lower the body temperature (note that the insulation board does not block the reducer's heat dissipation channel).

Shaft end heat protection: If the output shaft end is connected to a high-temperature load (such as a hot conveyor belt), a thermal insulation sleeve (such as wrapped in asbestos cloth and metal shell) can be added to the shaft end, or an adaptive design with air-cooled shaft end can be selected to prevent heat from being transmitted along the shaft to the inside of the box, affecting the bearings and lubrication system.