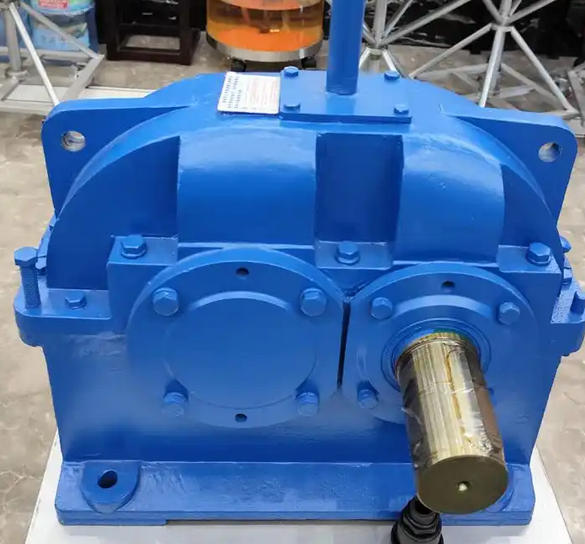

What safety precautions should be taken during the horizontal adjustment process of the motor and ZDY280-5.6-1 reducer

Leveling adjustment requires strict adherence to the principle of "safety first, standardized operation", with a focus on preventing risks such as equipment tilting, mechanical injury, and electric shock, to ensure the safety of personnel and equipment.1、 Safety preparation before homework

Shut down the machine, cut off the power, hang a tag and lock it, disconnect the motor power switch, hang a "under maintenance, no closing" sign to prevent others from accidentally starting the equipment.

Check the work environment, clean up surrounding debris, reserve sufficient operating space, ensure the ground is flat and free of oil stains, and avoid slipping and falling injuries.

Wear protective equipment, safety helmets, anti smashing gloves, and anti slip shoes. If high-altitude work is required (equipment base higher than 1.5m), fasten the safety belt and build a stable operating platform.

Check the safety of the tools, confirm that the jacks, shims, torque wrenches, and other tools are not damaged or fatigued, and that their load-bearing capacity matches the weight of the equipment (ZDY280-5.6-1 reducer+motor weighs about several hundred kilograms).

2、 Adjustment process safety points

The equipment support is stable. When adjusting with a jack, anti slip pads should be placed under the equipment base, and the jack should be placed vertically. It is forbidden to tilt and bear force to prevent the equipment from slipping and tilting.

Slowly adjust step by step, with each adjustment not exceeding 5mm in height, to avoid equipment imbalance caused by a large one-time lifting. During the adjustment process, assign a dedicated person to monitor and observe whether there are any signs of displacement or shaking of the equipment.

Prohibit unauthorized operations. Do not directly insert your hands into the gaps between the equipment base, pad iron, or ground. If thin steel sheets need to be filled, use tools to assist in pushing to prevent squeezing your hands.

To avoid component damage, it is forbidden to strike precision parts such as the gearbox housing and motor end cover during adjustment to prevent deformation from affecting equipment accuracy. When tightening the anchor bolts, uniform force should be applied according to the specified torque to avoid bolt breakage.

3、 Post homework safety review

Clean up the on-site tools and remove the jacks, shims, and other tools from under the equipment to avoid equipment malfunctions caused by squeezing the tools during operation.

Remove the safety label, confirm that the device has been adjusted and securely fixed, then remove the "Do Not Close" label and restore the power connection.

Observe the no-load test machine, inform surrounding personnel to stay away before starting the equipment, monitor for any abnormal noise or vibration during the test machine, and immediately stop the machine and cut off the power for inspection if any problems occur.