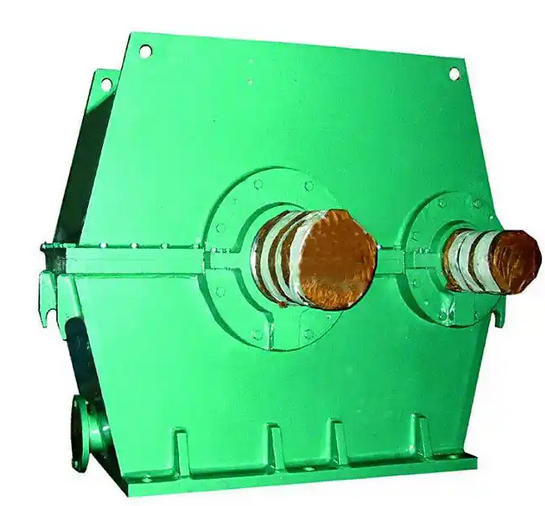

How to verify whether the torque of MBY1000-5 gear reducer meets the requirements

To verify whether the torque of MBY1000-5 gear reducer meets the requirements, a comprehensive evaluation is required through three steps: theoretical calculation, actual measurement comparison, and working condition verification. The specific method is as follows:1、 Theoretical calculation verification

1. Load torque calculation

Calculate the required torque based on load characteristics (mass, friction coefficient, type of motion):

Horizontal movement: T=F × r × η (F is the frictional force, r is the radius, and η is the transmission efficiency)

Vertical lifting: T=m × g × r × η (m is mass, g is gravitational acceleration)

When considering acceleration, add the inertia torque term:

(J is the moment of inertia, α is the angular acceleration)

2. Safety factor verification

Total required torque=load torque+inertia torque, multiplied by a safety factor (1.5~3), compared with the rated torque of the gearbox

2、 Tested torque verification

Torque sensor measurement

If it continues to exceed 120% of the rated torque (such as MBY1000-5 rated torque of XX N · m), it is judged as overload

Install a torque sensor on the output shaft to monitor the actual torque in real-time

Indirect calculation of current/power

Measure the input current of the motor with a clamp meter. If it continues to exceed the rated current by 110% (e.g. rated 10A, measured>11A), it will prompt overload

The power meter detects the input power, and when overloaded, the power increases by more than 15% compared to normal operating conditions

3、 Verification and adjustment of working conditions

Trial operation testing

No load operation: Check if the vibration (≤ 2.5mm/s), noise (≤ 85dB (A)), and temperature rise (oil temperature ≤ 80 ℃) are normal

Step loading: gradually increase from 25% to 100% rated load, observe transmission efficiency (current fluctuation ≤ 10%) and temperature rise curve

Exception handling

If there is periodic vibration or sudden increase in current, it is necessary to check the gear meshing marks (contact area ≥ 70%) or bearing wear

4、 Key data reference

MBY1000-5 rated torque: Please refer to the manufacturer's manual (such as the technical parameters provided by 1688 merchants)

Lubrication requirements: L-CKD 320 lubricating oil is recommended, with a stable oil pressure of 0.4MPa ± 10%

The above method can systematically verify the torque matching and ensure the safe operation of the equipment. If the calculation or actual measurement does not meet the standard, it is necessary to replace with a higher torque model or optimize the transmission scheme