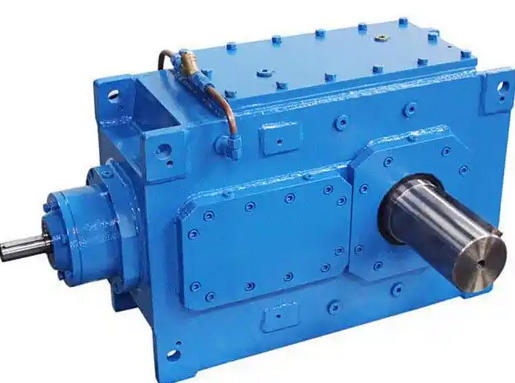

How to improve the gear transmission efficiency of B3SH12 reducer by grinding process and shape correction technology

In the field of industrial transmission, the gear transmission efficiency of B3SH12 reducer, as a key component, directly affects the energy consumption, performance, and operational stability of the entire equipment. Grinding process and shape correction technology, as important means to improve the quality of gear transmission, have been widely used in reducer manufacturing in recent years. By precision grinding the gear tooth surface and making reasonable corrections to the tooth shape and orientation, the meshing condition of the gear can be effectively improved, energy loss can be reduced, and the gear transmission efficiency of B3SH12 reducer can be significantly improved.1、 The role of gear grinding technology in improving transmission efficiency

1. Eliminate heat treatment deformation and improve gear accuracy

After heat treatment, the gear of B3SH12 reducer will inevitably undergo certain deformation, which will affect the accuracy and meshing performance of the gear. Grinding technology is an effective means to solve this problem, which uses a grinding wheel as a tool to perform precision machining on quenched gears. In high-speed and heavy-duty work scenarios, such as the application of B3SH12 reducers to large industrial equipment, extremely high gear accuracy is required. The gear grinding process can achieve a gear accuracy of 6 to 3 levels (according to the JB179-83 standard) or even higher, greatly reducing tooth profile and orientation errors. Taking the grinding of teeth with a conical grinding wheel as an example, the grinding wheel performs reciprocating motion along the tooth length direction, and the workpiece rotates and moves, which can accurately grind the side of the tooth groove, making the tooth surface contact of the gear more uniform during the meshing process, reducing the friction loss caused by uneven tooth surface, and effectively improving the transmission efficiency.

2. Reduce tooth surface roughness and decrease frictional resistance

Grinding machining can reduce the roughness ra value of gear tooth surface to 0.4-0.2 μ m, and extremely smooth tooth surface can significantly reduce the friction coefficient. When the B3SH12 reducer is running, the smooth tooth surface makes the relative sliding between gears smoother, reduces the adhesive wear and plowing effect between tooth surfaces, and lowers the frictional power consumption. In the process of gear transmission, lubricating oil forms an oil film between the tooth surfaces, and a smooth tooth surface helps maintain the stability of the oil film, further reducing frictional resistance. Compared to machining methods such as gear shaving and honing, gear grinding performs better in reducing tooth surface roughness and can better meet the high-efficiency transmission requirements of B3SH12 reducers.