MVBR040L1 planetary reducer internal gear operation mechanism

Internal gear operation mechanism of MVBR040L1 planetary gearbox

The MVBR040L1 planetary gearbox has been widely used in many fields due to its efficient transmission performance, and the operating mechanism of its internal gears is the key to achieving this performance.

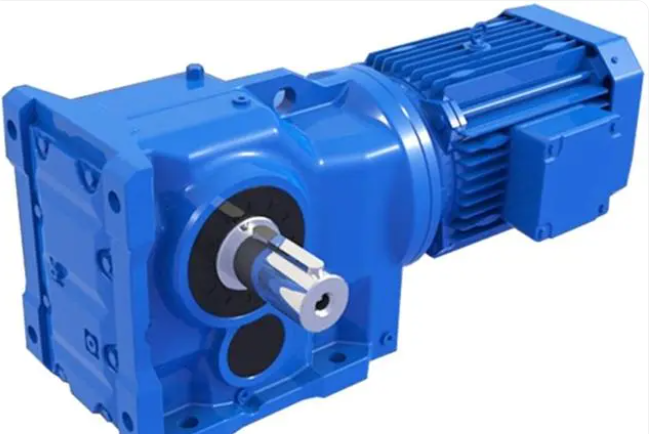

The interior of the planetary gearbox is mainly composed of a sun gear, planetary gears, and an inner ring gear. Its operating mechanism can be metaphorically described as a planetary system, where the sun gear is located at the center like a star, the planetary gears are like planets rotating around the sun gear, and the internal gear ring is equivalent to the orbit of planetary motion.

When power is input to the sun gear, the sun gear begins to rotate. Due to the meshing between the sun gear and the planet gears, the rotation of the sun gear will drive the planet gears to revolve around the sun gear. At the same time, the planetary gear itself is also undergoing rotation. The shaft of the planetary gear is connected to the output shaft through a connector, thereby transmitting power.

During this operation, multiple planetary gears are evenly distributed around the sun gear, sharing the load together. This structural design enables the planetary gearbox to withstand large torques and loads. At the same time, due to the participation of multiple planetary gears in the transmission, the transmission is smoother, reducing vibration and noise.

The meshing between the planetary gear, sun gear, and internal gear ring is the key to achieving deceleration. By designing the gear ratios of the sun gear, planetary gear, and inner ring gear reasonably, different reduction ratios can be obtained. When the number of teeth on the sun gear is small and the number of teeth on the inner ring gear is large, the planetary gears need to revolve around the sun gear multiple times for each revolution, thus achieving the effect of deceleration.

In addition, the gears inside planetary gearboxes are usually made of high-strength alloy steel materials and undergo precision machining and heat treatment processes to ensure the strength, hardness, and wear resistance of the gears. At the same time, in order to ensure the meshing accuracy and transmission efficiency of gears, the machining accuracy of gears is very high, and CNC machining equipment is usually used for machining.

In short, the operating mechanism of the internal gears of MVBR040L1 planetary gearbox is a complex and precise system. Efficient deceleration and torque amplification functions are achieved through the interaction of the sun gear, planetary gear, and internal gear ring. This operating mechanism makes planetary gearboxes have a wide range of application prospects in industrial production.