How to determine if the noise of CWS125-31.5-2F worm gear reducer is normal

To determine whether the noise of the CWS125-31.5-2F worm gear reducer is normal, it is necessary to combine its structural characteristics (center distance of 125mm, transmission ratio of 31.5, with fan cooling), industry standards, operating conditions, and abnormal noise characteristics, and comprehensively judge it in three dimensions through "benchmark value comparison+working condition adaptability+abnormal signal recognition". The specific method is as follows:1、 First, clarify the core benchmark of normal noise (quantitative+qualitative)

1. Quantify the noise range (based on industry rules for reducers of the same specifications)

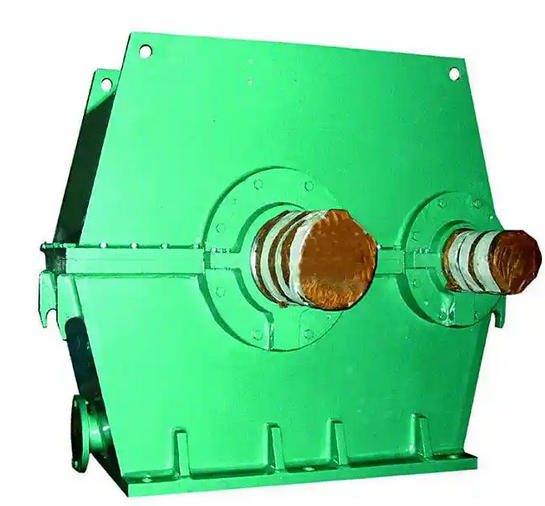

This model belongs to the medium-sized worm gear reducer, suitable for input speed ≤ 1500r/min, and the noise under normal working conditions needs to meet the following requirements:

Rated load (output torque in accordance with the manufacturer's calibration value): 65~75dB (A) (similar to the noise intensity of office printers or small fans, without any harsh feeling);

No load operation (no output load): 60-65dB (A) (close to normal indoor conversation sound, no obvious mechanical friction sound);

Fan cooling device superimposed noise: Equipped with an "F" level fan, the normal fan noise is 5-8dB (A), which needs to be included in the total noise range mentioned above (if the fan emits sharp abnormal noise alone, it belongs to fan failure, not gearbox body noise).

Measurement conditions: 1m away from the gearbox housing, level with the axis, environmental noise ≤ 55dB (A) (to avoid background noise interference), measured using a decibel meter (weighted by A), and recorded continuously for 3 minutes to take the average value.

2. Qualitative noise characteristics (3 key attributes of normal noise)

Sound quality: mainly characterized by "smooth low-frequency roar", without sharp whistling, metallic impact sound, or periodic abnormal noise;

Stability: Noise value fluctuation ≤ 3dB (A), with gentle changes in load/speed (such as slow increase in noise without sudden changes when the load increases);

Correlation: After the fan is started, the noise only slightly increases (within 5dB) without any additional noise; There is no residual noise such as "click" or "friction" when stopping the machine.

2、 Judging based on working conditions: noise adaptability in different scenarios

Normal noise should be matched with operating conditions to avoid misjudging "reasonable noise caused by operating conditions" as abnormal:

Load condition:

Reasonable range: When the load is ≤ 110% of the rated value, the noise can rise to 75-80dB (A) (short-term peak, not sustained);

Abnormal signal: The load does not exceed the rated value, but the noise suddenly exceeds 80dB (A), or accompanied by "cracking sound" or "high-frequency whistling" (possibly due to poor tooth contact or overload).

Speed condition:

Reasonable range: When the input speed is 1000~1500r/min, the noise increases linearly with the increase of speed (for every 300r/min increase, the noise increases by 3~5dB (A));

Abnormal signal: There is still sharp noise at low speeds (such as input speed below 500r/min), or the speed is stable but the noise fluctuation exceeds 5dB (A) (possibly due to bearing wear or assembly deviation).