Introduction to SEW X-Series Industrial Gear Units

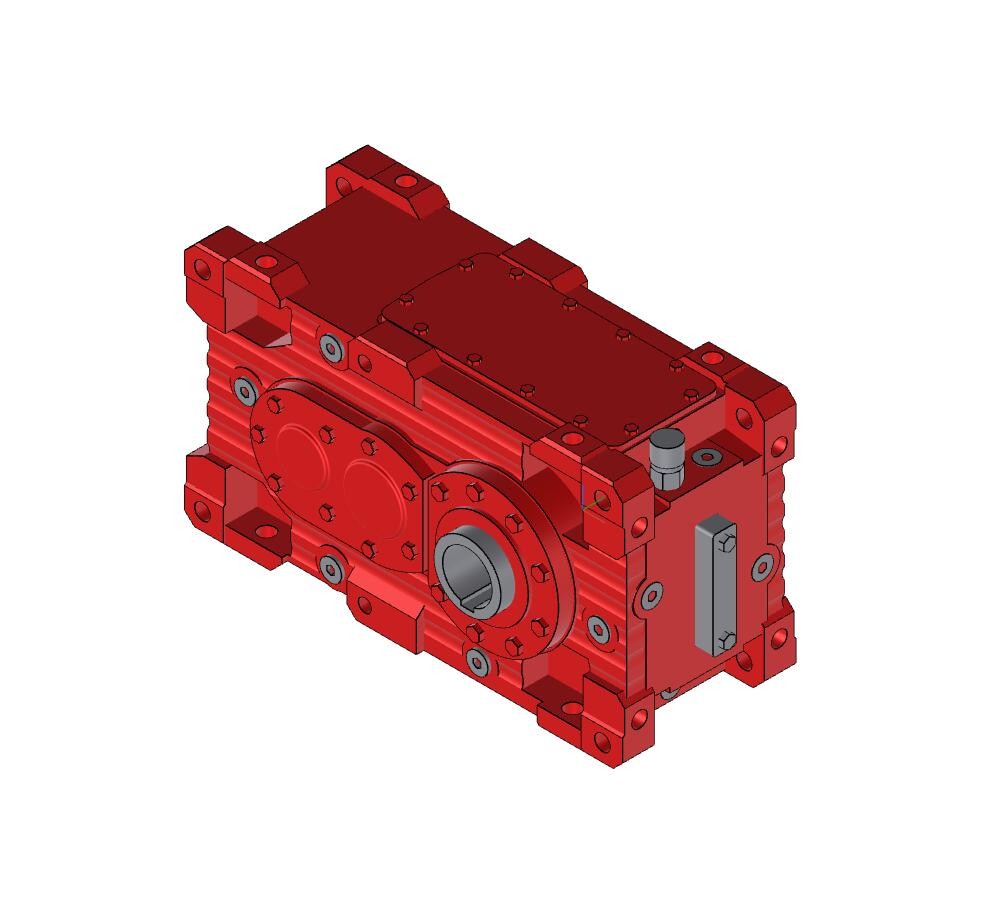

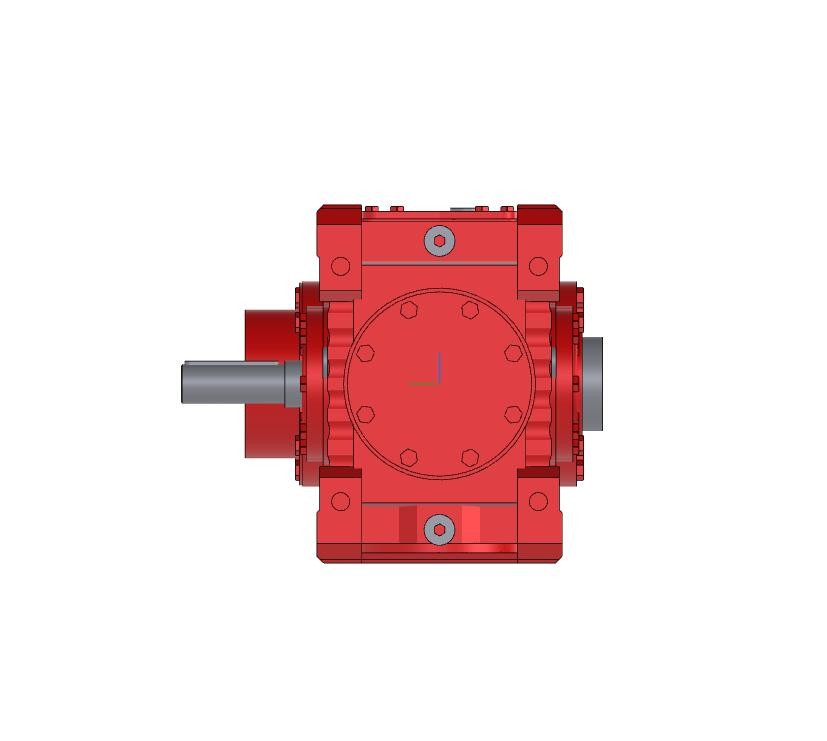

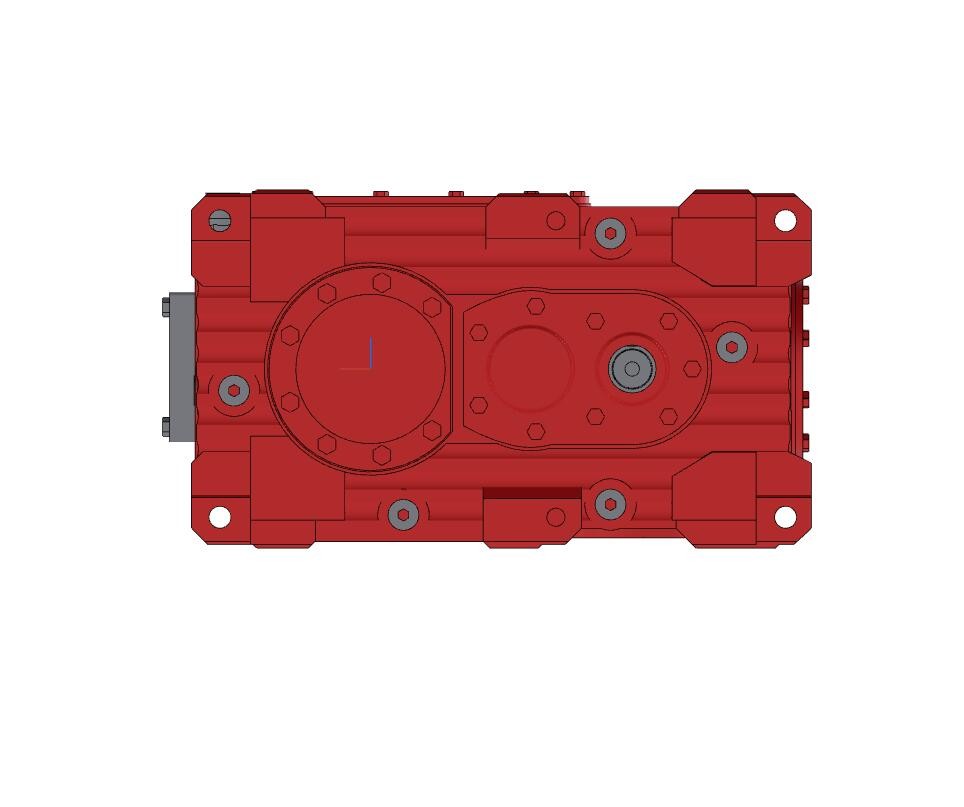

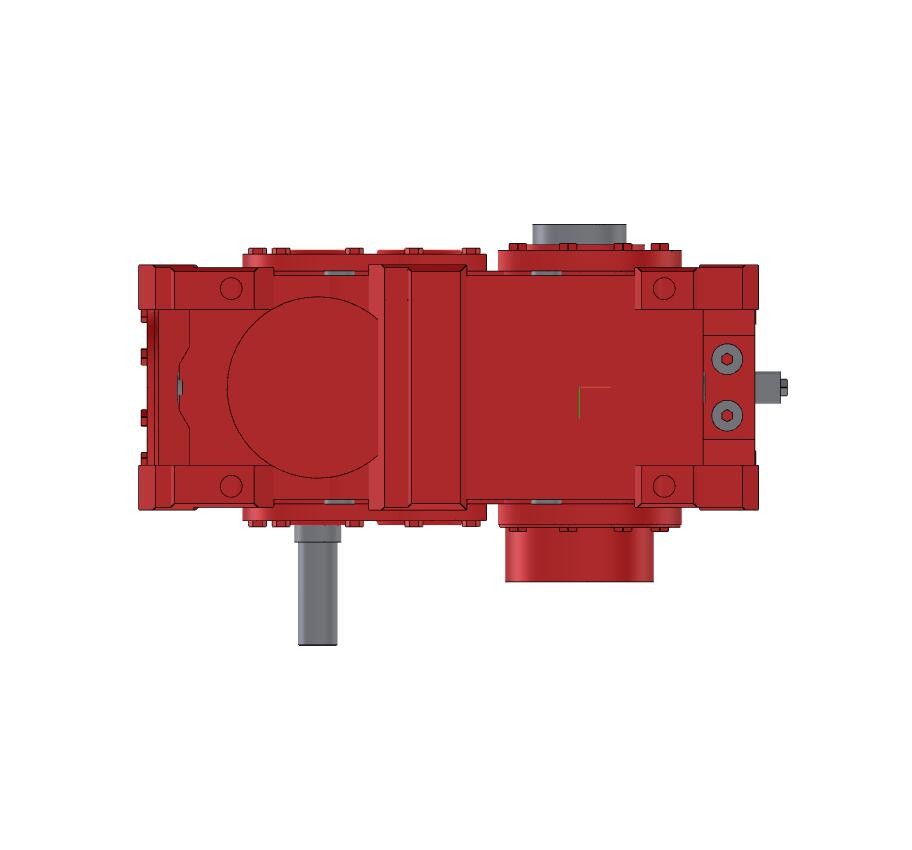

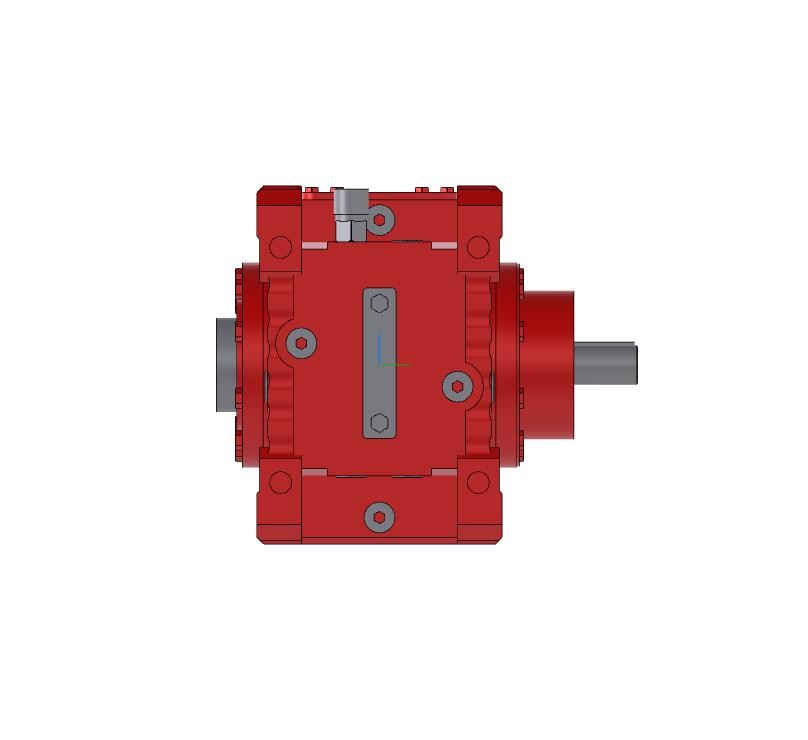

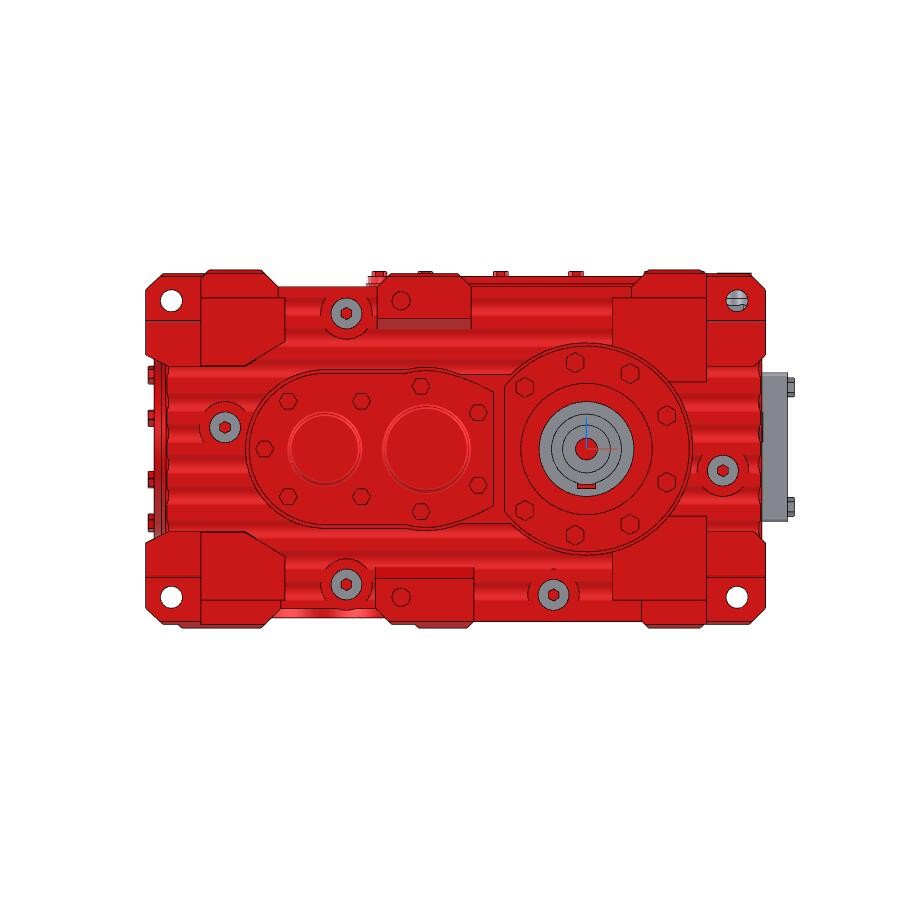

The SEW X-Series industrial gear units are independent industrial gearbox platform products launched by SEW-EURODRIVE Germany. They include two main types: helical gear (Type F) and bevel-helical gear (Types K/T), with multiple transmission stages of 2, 3, and 4. Adaptable to harsh working conditions, they are widely used in industrial scenarios such as material handling, hoisting, and mixing.

Core Structure and Design Highlights

1. Housing Design: Adopting integrated or split housing, it has both ultra-high rigidity and impact resistance, capable of withstanding heavy loads and vibrations under extreme working conditions. The innovative reversible housing design enables quick switching of left and right shaft positions, greatly reducing model inventory and adapting to diverse installation requirements. The housing is axially symmetrical, allowing installation on both sides, and is equipped with various installation methods such as base, torque arm, and flange, featuring extremely high versatility.

2. Transmission System: The gears undergo precision machining and tooth surface hardening treatment, resulting in high meshing accuracy, low operating noise, and a transmission efficiency of 96%-98%. The modular design covers 23 sub-specifications, with a torque range of 6.8-475kNm and a speed ratio range of 6.3-450, which can accurately match the load and avoid waste caused by oversized equipment selection.

3. Cooling and Maintenance: Equipped with a patented high-efficiency cooling system (optional fan/coil cooling), it is suitable for high-temperature environments, effectively controlling oil temperature and extending service life. The split housing and standardized interfaces facilitate maintenance, and combined with 2D/3D drawing tools, significantly shorten the engineering planning cycle, with fast delivery of standard models.

Key Technical Parameters

|

Parameter Category |

Specific Value |

|

Torque Range |

6.8kNm - 475kNm |

|

Transmission Stages |

2/3/4 stages |

|

Speed Ratio Range |

6.3-450 |

|

Gear Type |

Helical Gear (F), Bevel-Helical Gear (K/T) |

|

Installation Method |

Multiple universal mounting positions such as base, torque arm, and flange |

|

Cooling Method |

Fan Cooling, Coil Cooling, Natural Cooling |

|

Protection Class |

IP54/IP65 (Optional) |

Typical Application Scenarios

With high reliability and adaptability, the X-Series covers core equipment in multiple industries:

4. Bulk Material Handling: Belt conveyors, bucket elevators, and screw conveyors in industries such as construction materials, mining, chemicals, and grain, adapting to high-load handling requirements of 700-1500 tons per hour.

5. Heavy Industry Manufacturing: Agitators, mixers, crushers, and shredders in wood processing, papermaking, and environmental protection fields, withstanding harsh environments such as dust and corrosion.

6. Hoisting and Logistics: Traction and lifting drives of container cranes in assembly workshops and ports, meeting high-frequency start-stop and heavy-load working conditions.

7. Special Working Conditions: Suitable for continuous operation equipment in sewage treatment, metallurgy, and other fields, providing customized sealing and anti-corrosion solutions.

Core Advantages and Values

8. High Efficiency and Energy Saving: The high power density design reduces weight while ensuring output, lowering energy consumption and procurement costs. Precise selection and efficient transmission reduce energy loss, which can significantly reduce comprehensive costs during long-term operation.

9. Stability and Reliability: The robust housing and precision gear design are suitable for environments from -30℃ to +40℃, and maintain stable operation under working conditions such as dust, impact, and humidity. The global service network and fast spare parts supply ensure continuous equipment operation.

10. Flexible Adaptability: Modular accessories (backstops, oil seals, shaft-end pumps, etc.) can be quickly combined to meet customer customized needs. The reversible housing and universal installation design shorten the project cycle and reduce inventory pressure.

In conclusion, with the core advantages of "robustness, high efficiency, and flexibility", the SEW X-Series has become a benchmark product in the industrial transmission field. It provides reliable power solutions for various heavy-load equipment, helping enterprises improve production efficiency and reduce operation and maintenance costs.

X2 series: X2F, X2FA, X2FH, X2K, X2KA, X2KH

X3 series: X3F, X3FA, X3FH, X3K, X3KA, X3KH, X3T, X3TA, X3TH

X4 series: X4F, X4FA, X4FH, X4K, X4KA, X4KH, X4T, X4TA, X4TH

305_X series All drawings English

SEW X-series models and weight

| X.FA..series | X.FH..series | X.K.series | X.KA.series | X.KH.series | X.T..series | X.TA.series | X.TH.series | |||||||||||||||

| model | kg | model | kg | model | kg | model | kg | model | kg | model | kg | model | kg | model | kg | |||||||

| X2FA100 | 210 | X2FH100 | 220 | X2K.100 | 335 | X2KA100 | 325 | X2KH100 | 335 | X3T.100 | 260 | X3TA100 | 250 | X3TH100 | 260 | |||||||

| X2FA110 | 225 | X2FH110 | 235 | X2K.110 | 350 | X2KA110 | 340 | X2KH110 | 350 | X3T.110 | 280 | X3TA110 | 270 | X3TH110 | 280 | |||||||

| X2FA120 | 300 | X2FH120 | 310 | X2K.120 | 430 | X2KA120 | 410 | X2KH120 | 420 | X3T.120 | 370 | X3TA120 | 350 | X3TH120 | 360 | |||||||

| X2FA130 | 315 | X2FH130 | 330 | X2K.130 | 465 | X2KA130 | 440 | X2KH130 | 455 | X3T.130 | 395 | X3TA130 | 370 | X3TH130 | 380 | |||||||

| X2FA140 | 495 | X2FH140 | 520 | X2K.140 | 520 | X2KA140 | 485 | X2KH140 | 510 | X3T.140 | 570 | X3TA140 | 535 | X3TH140 | 545 | |||||||

| X2FA150 | 520 | X2FH150 | 550 | X2K.150 | 550 | X2KA150 | 500 | X2KH150 | 530 | X3T.150 | 615 | X3TA150 | 565 | X3TH150 | 575 | |||||||

| X2FA160 | 805 | X2FH160 | 835 | X2K.160 | 825 | X2KA160 | 755 | X2KH160 | 785 | X3T.160 | 945 | X3TA160 | 875 | X3TH160 | 900 | |||||||

| X2FA170 | 930 | X2FH170 | 985 | X2K.170 | 885 | X2KA170 | 875 | X2KH170 | 930 | X3T.170 | 1015 | X3TA170 | 1005 | X3TH170 | 1060 | |||||||

| X2FA180 | 1120 | X2FH180 | 1130 | X2K.180 | 1280 | X2KA180 | 1190 | X2KH180 | 1210 | X3T.180 | 1326 | X3TA180 | 1215 | X3TH180 | 1229 | |||||||

| X2FA190 | 1180 | X2FH190 | 1190 | X2K.190 | 1400 | X2KA190 | 1300 | X2KH190 | 1320 | X3T.190 | 1397 | X3TA190 | 1286 | X3TH190 | 1300 | |||||||

| X2FA200 | 1590 | X2FH200 | 1620 | X2K.200 | 1720 | X2KA200 | 1600 | X2KH200 | 1630 | X3T.200 | 1847 | X3TA200 | 1747 | X3TH200 | 1776 | |||||||

| X2FA210 | 1670 | X2FH210 | 1710 | X2K.210 | 1840 | X2KA210 | 1690 | X2KH210 | 1740 | X3T.210 | 1975 | X3TA210 | 1845 | X3TH210 | 1880 | |||||||

| X2FA220 | 2200 | X2FH220 | 2280 | X2K.220 | 2520 | X2KA220 | 2390 | X2KH220 | 2430 | X3T.220 | 2548 | X3TA220 | 2323 | X3TH220 | 2405 | |||||||

| X2FA230 | 2330 | X2FH230 | 2410 | X2K.230 | 2690 | X2KA230 | 2570 | X2KH230 | 2610 | X3T.230 | 2718 | X3TA230 | 2493 | X3TH230 | 2575 | |||||||

| X2FA240 | 3020 | X2FH240 | 3100 | X2K.240 | 3520 | X2KA240 | 3190 | X2KH240 | 3260 | X3T.240 | 3556 | X3TA240 | 3265 | X3TH240 | 3338 | |||||||

| X2FA250 | 3200 | X2FH250 | 3270 | X2K.250 | 3700 | X2KA250 | 3270 | X2KH250 | 3340 | X3T.250 | 3655 | X3TA250 | 3342 | X3TH250 | 3411 | |||||||

| X2FA260 | 4050 | X2FH260 | 4200 | X3K.100 | 255 | X3KA100 | 245 | X3KH100 | 255 | X4T.120 | 420 | X4TA120 | 380 | X4TH120 | 390 | |||||||

| X2FA270 | 4450 | X2FH270 | 4700 | X3K.110 | 275 | X3KA110 | 265 | X3KH110 | 275 | X4T.130 | 450 | X4TA130 | 410 | X4TH130 | 425 | |||||||

| X2FA280 | 4850 | X2FH280 | 5100 | X3K.120 | 360 | X3KA120 | 340 | X3KH120 | 350 | X4T.140 | 605 | X4TA140 | 550 | X4TH140 | 575 | |||||||

| X2FA290 | 5900 | X2FH290 | 6150 | X3K.130 | 385 | X3KA130 | 360 | X3KH130 | 370 | X4T.150 | 650 | X4TA150 | 590 | X4TH150 | 620 | |||||||

| X2FA300 | 6550 | X2FH300 | 6800 | X3K.140 | 560 | X3KA140 | 525 | X3KH140 | 535 | X4T.160 | 1010 | X4TA160 | 915 | X4TH160 | 945 | |||||||

| X2FA310 | 6750 | X2FH310 | 7100 | X3K.150 | 605 | X3KA150 | 555 | X3KH150 | 565 | X4T.170 | 1060 | X4TA170 | 960 | X4TH170 | 1015 | |||||||

| X2FA320 | 7500 | X2FH320 | 7850 | X3K.160 | 925 | X3KA160 | 855 | X3KH160 | 860 | X4T.180 | 1359 | X4TA180 | 1248 | X4TH180 | 1262 | |||||||

| X3FA100 | 210 | X3FH100 | 220 | X3K.170 | 995 | X3KA170 | 985 | X3KH170 | 1040 | X4T.190 | 1422 | X4TA190 | 1311 | X4TH190 | 1325 | |||||||

| X3FA110 | 215 | X3FH110 | 225 | X3K.180 | 1230 | X3KA180 | 1120 | X3KH180 | 1140 | X4T.200 | 1811 | X4TA200 | 1711 | X4TH200 | 1740 | |||||||

| X3FA120 | 370 | X3FH120 | 380 | X3K.190 | 1420 | X3KA190 | 1310 | X3KH190 | 1330 | X4T.210 | 1950 | X4TA210 | 1820 | X4TH210 | 1855 | |||||||

| X3FA130 | 395 | X3FH130 | 405 | X3K.200 | 1950 | X3KA200 | 1850 | X3KH200 | 1880 | X4T.220 | 2468 | X4TA220 | 2243 | X4TH220 | 2325 | |||||||

| X3FA140 | 530 | X3FH140 | 540 | X3K.210 | 2080 | X3KA210 | 1950 | X3KH210 | 1980 | X4T.230 | 2725 | X4TA230 | 2500 | X4TH230 | 2582 | |||||||

| X3FA150 | 560 | X3FH150 | 575 | X3K.220 | 2560 | X3KA220 | 2330 | X3KH220 | 2410 | X4T.240 | 3467 | X4TA240 | 3176 | X4TH240 | 3249 | |||||||

| X3FA160 | 850 | X3FH160 | 880 | X3K.230 | 2690 | X3KA230 | 2470 | X3KH230 | 2550 | X4T.250 | 3566 | X4TA250 | 3253 | X4TH250 | 3322 | |||||||

| X3FA170 | 985 | X3FH170 | 1040 | X3K.240 | 3500 | X3KA240 | 3200 | X3KH240 | 3280 | |||||||||||||

| X3FA180 | 1230 | X3FH180 | 1240 | X3K.250 | 3600 | X3KA250 | 3280 | X3KH250 | 3350 | |||||||||||||

| X3FA190 | 1290 | X3FH190 | 1300 | X3K.260 | 4850 | X3KA260 | 4400 | X3KH260 | 4550 | |||||||||||||

| X3FA200 | 1590 | X3FH200 | 1620 | X3K.270 | 5350 | X3KA270 | 4850 | X3KH270 | 5100 | |||||||||||||

| X3FA210 | 1670 | X3FH210 | 1710 | X3K.280 | 5850 | X3KA280 | 5300 | X3KH280 | 5550 | |||||||||||||

| X3FA220 | 2230 | X3FH220 | 2320 | X3K.290 | 7000 | X3KA290 | 6350 | X3KH290 | 6400 | |||||||||||||

| X3FA230 | 2390 | X3FH230 | 2480 | X3K.300 | 7700 | X3KA300 | 6950 | X3KH300 | 7200 | |||||||||||||

| X3FA240 | 3010 | X3FH240 | 3090 | X3K.310 | 8550 | X3KA310 | 7700 | X3KH310 | 8050 | |||||||||||||

| X3FA250 | 3190 | X3FH250 | 3260 | X3K.320 | 9450 | X3KA320 | 8400 | X3KH320 | 8750 | |||||||||||||

| X3FA260 | 4050 | X3FH260 | 4200 | X4K.120 | 405 | X4KA120 | 365 | X4KH120 | 375 | |||||||||||||

| X3FA270 | 4450 | X3FH270 | 4750 | X4K.130 | 435 | X4KA130 | 395 | X4KH130 | 410 | |||||||||||||

| X3FA280 | 4950 | X3FH280 | 5300 | X4K.140 | 590 | X4KA140 | 535 | X4KH140 | 560 | |||||||||||||

| X3FA290 | 6250 | X3FH290 | ||||||||||||||||||||

305_X series All drawings English

X.. Series Industrial Gear Units English

X.. Series Helical and Bevel-Helical Gear Units Chinese

X.. Series Helical and Bevel-Helical Gear Units English

X..e Series Bevel-Helical Gear Units Bucket Elevator Drives English

1. SEW X-series models and weight

2 X-series models and weight lookup table 2

Explanation of the X-series model composition

Explanation of the X-series model composition

2.13 Type designations

2.13.1 Gear unitsThe following example shows the structure of the type designation:

|

X3KS250 /HU /B |

|

|

X |

Industrial gear unit series |

|

3 |

Number of gear unit stages • 2 = 2 stages • 3 = 3 stages • 4 = 4 stages |

|

K |

Gear unit design • F = Helical gear unit • K = Bevel-helical gear unit • T = Bevel-helical gear unit |

|

S |

Type of output shaft • S = Solid shaft with key • R = Smooth solid shaft • L = Splined solid shaft • A = Hollow shaft with keyway • H = Hollow shaft with shrink disk • V = Splined hollow shaft • T = Hollow shaft with TorqLOC® hollow shaft mounting system • C = Reinforced solid shaft with key |

|

|

Application • B = Bucket elevator gear unit • C = Hoist gear unit |

|

250 |

Gear unit sizes •100 – 320 |

|

HU |

Housing design • HU = Universal housing • HH = Horizontal housing • /HA = Agitator housing • HT = Thermal housing • HC = Hoist housing |

|

B |

Gear unit mounting • /B = Foot • /T = Torque arm • /F = Flange |

2.13.2 Flange couplings

The following example shows the structure of the type designation.

|

FC530/175SM |

|

|

FC |

Rigid flange coupling |

|

530 |

Outer diameter of the flange |

|

175 |

Bore diameter |

|

S |

Type of shaft-hub connection: • S = Cylindrical interference fit • K = Keyed connection • T = Conical interference fit |

|

M |

Type of centering: • M = External centering • F = Internal centering |

2.13.3 Abbreviations for optional accessories

The table shows the abbreviations used and what they mean.

|

Abbreviation |

Meaning |

|

BF |

Base frame |

|

BS |

Backstop |

|

BPG |

Breather |

|

CCV |

Water cooling cover |

|

CCT |

Water cooling cartridge |

|

F |

Mounting flange |

|

FC |

Flange coupling |

|

FAN |

Fan |

|

FAN-ADV |

Fan, Advanced design |

|

ET |

Oil expansion tank |

|

HH |

Horizontal housing |

|

HU |

Universal housing |

|

HA |

Agitator housing |

|

HT |

Thermal housing |

|

AI |

Motor adapter |

|

SB |

Swing base |

|

SEP |

Shaft end pump |

|

T |

Torque arm |

|

OAC |

Circulation cooling oil-air cooler with motor pump |

|

OWC |

Circulation cooling oil-water cooler with motor pump |

|

OAP |

Circulation cooling oil-air cooler with pressure lubrication and motor pump |

|

OWP |

Circulation cooling oil-water cooler with pressure lubrication and motor pump |

|

ONP |

Pressure lubrication and motor pump |

|

ONP1/ONP1L |

Pressure lubrication and motor pump |

|

OD |

Oil dipstick |

|

ODV |

Oil drain valve |

|

OLG |

Oil level glass |

|

OH |

Oil heater |

|

VBD |

V-belt drives |

Explanation of the X-series model composition

1. SEW X-series models and weight ... 2 X-series models and weight lookup table 2

| X.FA..series | X.FH..series | X.K.series | X.KA.series | X.KH.series | X.T..series | X.TA.series | X.TH.series | |||||||||||||||

| model | kg | model | kg | model | kg | model | kg | model | kg | model | kg | model | kg | model | kg | |||||||

| X2FA100 | 210 | X2FH100 | 220 | X2K.100 | 335 | X2KA100 | 325 | X2KH100 | 335 | X3T.100 | 260 | X3TA100 | 250 | X3TH100 | 260 | |||||||

| X2FA110 | 225 | X2FH110 | 235 | X2K.110 | 350 | X2KA110 | 340 | X2KH110 | 350 | X3T.110 | 280 | X3TA110 | 270 | X3TH110 | 280 | |||||||

| X2FA120 | 300 | X2FH120 | 310 | X2K.120 | 430 | X2KA120 | 410 | X2KH120 | 420 | X3T.120 | 370 | X3TA120 | 350 | X3TH120 | 360 | |||||||

| X2FA130 | 315 | X2FH130 | 330 | X2K.130 | 465 | X2KA130 | 440 | X2KH130 | 455 | X3T.130 | 395 | X3TA130 | 370 | X3TH130 | 380 | |||||||

| X2FA140 | 495 | X2FH140 | 520 | X2K.140 | 520 | X2KA140 | 485 | X2KH140 | 510 | X3T.140 | 570 | X3TA140 | 535 | X3TH140 | 545 | |||||||

| X2FA150 | 520 | X2FH150 | 550 | X2K.150 | 550 | X2KA150 | 500 | X2KH150 | 530 | X3T.150 | 615 | X3TA150 | 565 | X3TH150 | 575 | |||||||

| X2FA160 | 805 | X2FH160 | 835 | X2K.160 | 825 | X2KA160 | 755 | X2KH160 | 785 | X3T.160 | 945 | X3TA160 | 875 | X3TH160 | 900 | |||||||

| X2FA170 | 930 | X2FH170 | 985 | X2K.170 | 885 | X2KA170 | 875 | X2KH170 | 930 | X3T.170 | 1015 | X3TA170 | 1005 | X3TH170 | 1060 | |||||||

| X2FA180 | 1120 | X2FH180 | 1130 | X2K.180 | 1280 | X2KA180 | 1190 | X2KH180 | 1210 | X3T.180 | 1326 | X3TA180 | 1215 | X3TH180 | 1229 | |||||||

| X2FA190 | 1180 | X2FH190 | 1190 | X2K.190 | 1400 | X2KA190 | 1300 | X2KH190 | 1320 | X3T.190 | 1397 | X3TA190 | 1286 | X3TH190 | 1300 | |||||||

| X2FA200 | 1590 | X2FH200 | 1620 | X2K.200 | 1720 | X2KA200 | 1600 | X2KH200 | 1630 | X3T.200 | 1847 | X3TA200 | 1747 | X3TH200 | 1776 | |||||||

| X2FA210 | 1670 | X2FH210 | 1710 | X2K.210 | 1840 | X2KA210 | 1690 | X2KH210 | 1740 | X3T.210 | 1975 | X3TA210 | 1845 | X3TH210 | 1880 | |||||||

| X2FA220 | 2200 | X2FH220 | 2280 | X2K.220 | 2520 | X2KA220 | 2390 | X2KH220 | 2430 | X3T.220 | 2548 | X3TA220 | 2323 | X3TH220 | 2405 | |||||||

| X2FA230 | 2330 | X2FH230 | 2410 | X2K.230 | 2690 | X2KA230 | 2570 | X2KH230 | 2610 | X3T.230 | 2718 | X3TA230 | 2493 | X3TH230 | 2575 | |||||||

| X2FA240 | 3020 | X2FH240 | 3100 | X2K.240 | 3520 | X2KA240 | 3190 | X2KH240 | 3260 | X3T.240 | 3556 | X3TA240 | 3265 | X3TH240 | 3338 | |||||||

| X2FA250 | 3200 | X2FH250 | 3270 | X2K.250 | 3700 | X2KA250 | 3270 | X2KH250 | 3340 | X3T.250 | 3655 | X3TA250 | 3342 | X3TH250 | 3411 | |||||||

| X2FA260 | 4050 | X2FH260 | 4200 | X3K.100 | 255 | X3KA100 | 245 | X3KH100 | 255 | X4T.120 | 420 | X4TA120 | 380 | X4TH120 | 390 | |||||||

| X2FA270 | 4450 | X2FH270 | 4700 | X3K.110 | 275 | X3KA110 | 265 | X3KH110 | 275 | X4T.130 | 450 | X4TA130 | 410 | X4TH130 | 425 | |||||||

| X2FA280 | 4850 | X2FH280 | 5100 | X3K.120 | 360 | X3KA120 | 340 | X3KH120 | 350 | X4T.140 | 605 | X4TA140 | 550 | X4TH140 | 575 | |||||||

| X2FA290 | 5900 | X2FH290 | 6150 | X3K.130 | 385 | X3KA130 | 360 | X3KH130 | 370 | X4T.150 | 650 | X4TA150 | 590 | X4TH150 | 620 | |||||||

| X2FA300 | 6550 | X2FH300 | 6800 | X3K.140 | 560 | X3KA140 | 525 | X3KH140 | 535 | X4T.160 | 1010 | X4TA160 | 915 | X4TH160 | 945 | |||||||

| X2FA310 | 6750 | X2FH310 | 7100 | X3K.150 | 605 | X3KA150 | 555 | X3KH150 | 565 | X4T.170 | 1060 | X4TA170 | 960 | X4TH170 | 1015 | |||||||

| X2FA320 | 7500 | X2FH320 | 7850 | X3K.160 | 925 | X3KA160 | 855 | X3KH160 | 860 | X4T.180 | 1359 | X4TA180 | 1248 | X4TH180 | 1262 | |||||||

| X3FA100 | 210 | X3FH100 | 220 | X3K.170 | 995 | X3KA170 | 985 | X3KH170 | 1040 | X4T.190 | 1422 | X4TA190 | 1311 | X4TH190 | 1325 | |||||||

| X3FA110 | 215 | X3FH110 | 225 | X3K.180 | 1230 | X3KA180 | 1120 | X3KH180 | 1140 | X4T.200 | 1811 | X4TA200 | 1711 | X4TH200 | 1740 | |||||||

| X3FA120 | 370 | X3FH120 | 380 | X3K.190 | 1420 | X3KA190 | 1310 | X3KH190 | 1330 | X4T.210 | 1950 | X4TA210 | 1820 | X4TH210 | 1855 | |||||||

| X3FA130 | 395 | X3FH130 | 405 | X3K.200 | 1950 | X3KA200 | 1850 | X3KH200 | 1880 | X4T.220 | 2468 | X4TA220 | 2243 | X4TH220 | 2325 | |||||||

| X3FA140 | 530 | X3FH140 | 540 | X3K.210 | 2080 | X3KA210 | 1950 | X3KH210 | 1980 | X4T.230 | 2725 | X4TA230 | 2500 | X4TH230 | 2582 | |||||||

| X3FA150 | 560 | X3FH150 | 575 | X3K.220 | 2560 | X3KA220 | 2330 | X3KH220 | 2410 | X4T.240 | 3467 | X4TA240 | 3176 | X4TH240 | 3249 | |||||||

| X3FA160 | 850 | X3FH160 | 880 | X3K.230 | 2690 | X3KA230 | 2470 | X3KH230 | 2550 | X4T.250 | 3566 | X4TA250 | 3253 | X4TH250 | 3322 | |||||||

| X3FA170 | 985 | X3FH170 | 1040 | X3K.240 | 3500 | X3KA240 | 3200 | X3KH240 | 3280 | |||||||||||||

| X3FA180 | 1230 | X3FH180 | 1240 | X3K.250 | 3600 | X3KA250 | 3280 | X3KH250 | 3350 | |||||||||||||

| X3FA190 | 1290 | X3FH190 | 1300 | X3K.260 | 4850 | X3KA260 | 4400 | X3KH260 | 4550 | |||||||||||||

| X3FA200 | 1590 | X3FH200 | 1620 | X3K.270 | 5350 | X3KA270 | 4850 | X3KH270 | 5100 | |||||||||||||

| X3FA210 | 1670 | X3FH210 | 1710 | X3K.280 | 5850 | X3KA280 | 5300 | X3KH280 | 5550 | |||||||||||||

| X3FA220 | 2230 | X3FH220 | 2320 | X3K.290 | 7000 | X3KA290 | 6350 | X3KH290 | 6400 | |||||||||||||

| X3FA230 | 2390 | X3FH230 | 2480 | X3K.300 | 7700 | X3KA300 | 6950 | X3KH300 | 7200 | |||||||||||||

| X3FA240 | 3010 | X3FH240 | 3090 | X3K.310 | 8550 | X3KA310 | 7700 | X3KH310 | 8050 | |||||||||||||

| X3FA250 | 3190 | X3FH250 | 3260 | X3K.320 | 9450 | X3KA320 | 8400 | X3KH320 | 8750 | |||||||||||||

| X3FA260 | 4050 | X3FH260 | 4200 | X4K.120 | 405 | X4KA120 | 365 | X4KH120 | 375 | |||||||||||||

| X3FA270 | 4450 | X3FH270 | 4750 | X4K.130 | 435 | X4KA130 | 395 | X4KH130 | 410 | |||||||||||||

| X3FA280 | 4950 | X3FH280 | 5300 | X4K.140 | 590 | X4KA140 | 535 | X4KH140 | 560 | |||||||||||||

| X3FA290 | 6250 | X3FH290 | 6500 | X4K.150 | 635 | X4KA150 | 575 | X4KH150 | 605 | |||||||||||||

| X3FA300 | 6850 | X3FH300 | 7100 | X4K.160 | 985 | X4KA160 | 890 | X4KH160 | 920 | |||||||||||||

| X3FA310 | 7650 | X3FH310 | 8000 | X4K.170 | 1035 | X4KA170 | 935 | X4KH170 | 990 | |||||||||||||

| X3FA320 | 8450 | X3FH320 | 8300 | X4K.180 | 1170 | X4KA180 | 1060 | X4KH180 | 1070 | |||||||||||||

| X4FA120 | 335 | X4FH120 | 345 | X4K.190 | 1360 | X4KA190 | 1250 | X4KH190 | 1270 | |||||||||||||

| X4FA130 | 355 | X4FH130 | 370 | X4K.200 | 1720 | X4KA200 | 1620 | X4KH200 | 1640 | |||||||||||||

| X4FA140 | 510 | X4FH140 | 535 | X4K.210 | 1850 | X4KA210 | 1720 | X4KH210 | 1760 | |||||||||||||

| X4FA150 | 545 | X4FH150 | 575 | X4K.220 | 2520 | X4KA220 | 2300 | X4KH220 | 2380 | |||||||||||||

| X4FA160 | 835 | X4FH160 | 865 | X4K.230 | 2670 | X4KA230 | 2450 | X4KH230 | 2530 | |||||||||||||

| X4FA170 | 900 | X4FH170 | 955 | X4K.240 | 3490 | X4KA240 | 3200 | X4KH240 | 3270 | |||||||||||||

SEW Industrial Gearboxes SEW Industrial Gearboxes .pdf

X2 Series: X2F, X2FA, X2FH, X2K, X2KA, X2KH

X3 Series: X3F, X3FA, X3FH, X3K, X3KA, X3KH, X3T, X3TA, X3TH

X4 Series: X4F, X4FA, X4FH, X4K, X4KA, X4KH, X4T, X4TA, X4TH

The core differences between SEW's X2, X3 and X4 series industrial gearboxes lie in size specifications, torque range, power rating, installation adaptability and optional configurations. The product line scales up progressively from X2 to X3 to X4 in terms of size and power output. In addition, compared with X2, X3 and X4 series add helical-bevel gear models with torque arm mounting (T/TA/TH), making them suitable for more complex working conditions.

I. Core Positioning and Specification Differences

|

Comparison Item |

X2 Series |

X3 Series |

X4 Series |

|

Power & Torque |

Low power and torque, suitable for light-load applications |

Medium power and torque, suitable for general-purpose applications |

High power and torque, suitable for heavy-duty applications |

|

Size Coverage |

Small size range, requiring compact installation space |

Medium size range, balancing space occupation and performance |

Large size range, meeting the installation requirements of high-load equipment |

|

Model Completeness |

Only available in two types: F (parallel-shaft helical gear) and K (right-angle helical-bevel gear) |

Includes F, K models plus newly added T (right-angle helical-bevel gear with torque arm mounting) models |

Includes F, K models plus T (right-angle helical-bevel gear with torque arm mounting) models |

|

Application Scenarios |

Small conveyors, packaging machinery, small mixing equipment |

General-purpose conveyors, auxiliary metallurgical equipment, papermaking machinery |

Large mining machinery, heavy-duty mixing devices, port hoisting equipment |

II. Meaning of Model Suffixes (Common to All Series, Determining Output Shaft Type and Mounting Method)

• F: Parallel-shaft helical gearbox, 2-4 stages of transmission, speed ratio ranging from 6.3 to 450, torque coverage from 6.8 to 475 kNm

• K: Right-angle helical-bevel gearbox, 2-4 stages of transmission, speed ratio ranging from 6.3 to 450, torque coverage from 6.8 to 475 kNm

• T: Right-angle helical-bevel gearbox with torque arm mounting, 3-4 stages of transmission, speed ratio ranging from 12.5 to 450, torque coverage from 6.8 to 175 kNm (only available for X3/X4 series)

• A: Hollow shaft with keyway

• H: Hollow shaft with shrink disk

• Note: T-type models are not available for X2 series; X3 and X4 series offer more comprehensive options for mounting and shaft configurations.

III. Key Performance and Design Differences

1. Load Capacity

○ X2: Features the smallest size and torque, designed for low-power, low-heat input scenarios with a compact structure and lower cost.

○ X3: Delivers medium load capacity, balancing strength and space requirements, and serves as the mainstream model for general industrial applications.

○ X4: Boasts the largest size and torque, adopting thicker gearbox housing, reinforced gears and bearings to handle continuous heavy-duty and shock load conditions.

2. Installation Flexibility

○ All three series support foot mounting and flange mounting (for F/K models of X2/X3/X4). X3 and X4 series additionally support torque arm mounting (for T series), making them suitable for space-constrained or elastic mounting scenarios.

○ The reversible housing design allows for left or right shaft output by flipping the housing, reducing the number of stock models and improving delivery efficiency.

3. Heat Dissipation and Maintenance Design

○ X2: Equipped with a basic heat dissipation structure, suitable for low-power, low-heat working conditions and easy to maintain.

○ X3: Features enhanced cooling fins, with an optional shaft-mounted pump for continuous operation under medium-power conditions.

○ X4: Comes with a high-efficiency cooling system (fan and cooling coil optional), ensuring stable oil temperature under heavy-duty conditions. The upgraded sealing and bearing specifications extend maintenance intervals.

4. Customization Capability

○ X2: Offers limited optional configurations, focusing on standardized light-load requirements.

○ X3: Available with optional motor adapters, backstops and various sealing systems, suitable for most industrial scenarios.

○ X4: Provides a full range of optional configurations, including explosion-proof (ATEX compliant) options, heavy-duty shaft systems and special lubrication systems, meeting the customization needs of extreme working conditions.

IV. Core Selection Recommendations

• For light load, limited space and cost-sensitive applications: Choose X2 series, preferably X2F/X2K models. Select A (hollow shaft with keyway) or H (hollow shaft with shrink disk) according to the shaft type requirements.

• For general-purpose applications requiring a balance between performance and cost: Choose X3 series. F/K models are suitable for conventional mounting, while T series is ideal for torque arm mounting scenarios.

• For heavy-duty, shock load and large-scale equipment applications: Choose X4 series, preferably X4K/X4T models. Pair with H (shrink disk) shaft type to enhance transmission reliability.