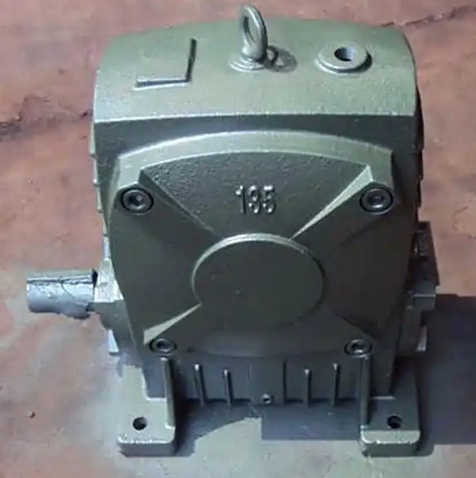

How to regularly check the connection status of the motor and ZSY160-40-I gear reducer

Regularly check the connection status between the motor and ZSY160-40-I gear reducer, with a key focus on conducting a comprehensive inspection once a month, paying attention to bolt tightness, coupling status, and operating parameters. Here are the specific operation guidelines:1、 Inspection cycle and tool preparation

Frequency: At least once a month, data must be recorded for each inspection.

Tools: Torque wrench (M16 bolt standard torque 80~120N · m), infrared thermometer, listening pin, dial gauge (used for centering detection).

2、 Inspection steps and judgment criteria

1. Tightness of bolts

Use a torque wrench to check the flange bolts and foundation bolts connecting the motor and reducer, ensuring that they are not loose.

Judgment criteria: The bolt has no slipping or rust, and the anti loosening washer is intact.

2. Coupling status

Visually inspect whether the elastic block is aged or broken, and whether the connecting bolts are loose.

Judgment criteria: The coupling has no friction marks and the protective cover is firm.

3. Operating parameters

Use an infrared thermometer to measure the temperature of the casing (≤ 100 ℃) and the temperature of the bearings (≤ 95 ℃).

Use a listening needle to compare the running sound. If there is any abnormal noise (such as metal impact sound), stop the machine for inspection.

4. Center detection

Measure the radial deviation (≤ 0.1mm) and axial end face parallelism (≤ 0.05mm/m) of the coupling using a dial gauge.

Judgment criteria: If the deviation is too large, the motor or load position needs to be adjusted.

3、 Safety and Records

Safety: Power off and hang a tag before inspection, wear a safety helmet and anti slip gloves.

Record: Establish a ledger to record oil level, temperature, and vibration values, and mark abnormal data in red.

By following the above steps, it is possible to effectively prevent faults such as loose connections and increased vibration, thereby extending the lifespan of the equipment.