What are the differences in lubricating oil requirements for different models of reducers

The differences in lubricating oil requirements for different models of reducers are mainly determined by four core factors: transmission structure, operating parameters, sealing form, and installation method. Specific differences can be listed in the following dimensions:1. Differentiate by transmission type

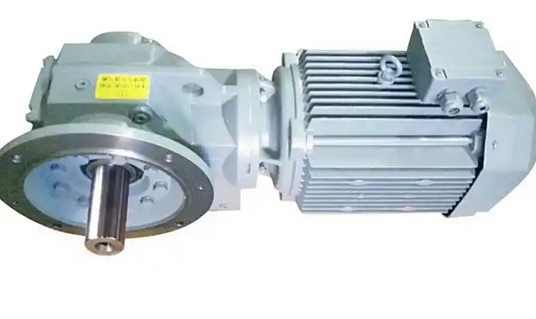

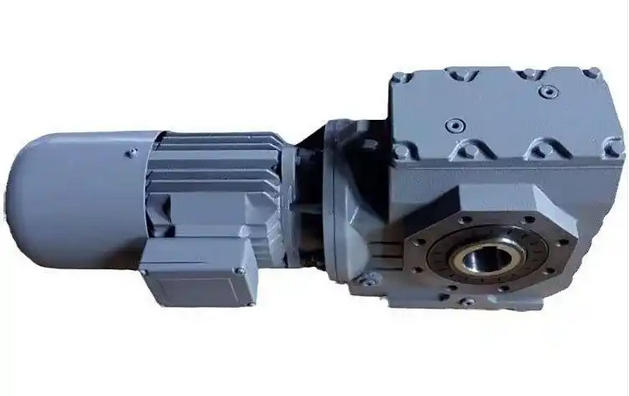

Gear reducers (such as cylindrical gears, bevel gears, and helical gear reducers): Emphasis should be placed on load-bearing and anti-wear properties, and medium/heavy-duty industrial gear oils (L-CKC/L-CKD series) should be preferred. The viscosity should match the gear module and operating speed; Choose high viscosity oil (460 #, 680 #) for heavy-duty gears with large modulus and low speed (such as reducers for cranes), and low viscosity oil (150 #, 220 #) for gears with high speed and low load.

Worm gear reducer: The worm gear is mostly made of copper material, and it is necessary to avoid the corrosion of copper parts by active sulfur additives in the oil. Special worm gear oil (L-CKE/P series) or gear oil without extreme pressure additives should be used; And due to the high sliding friction and heat generation of worm gear transmission, the oil needs to have excellent shear resistance and heat dissipation performance.

Planetary reducer: The transmission structure is compact, and the tooth contact stress is extremely high. The lubricating oil is required to have extreme pressure anti-wear and micro pitting resistance. Synthetic gear oil (such as PAO base oil) is preferred, and the viscosity grade is adjusted according to the reduction ratio and output torque.

2. Differentiate by operating condition parameters

Load difference: Light load reducers (such as those used in small conveying equipment) can use ordinary medium load gear oil; Heavy load and impact load reducers (such as those used in metallurgy and mining equipment) require the use of heavy-duty gear oil (L-CKD) or specialized oil with extreme pressure additives.

Temperature difference: High temperature conditions (such as near kilns or continuous long-term operation) require the use of synthetic oils with high viscosity index and strong antioxidant properties to avoid rapid oxidation and deterioration of the oil; Low temperature working conditions (such as outdoor low-temperature environments) require the use of low pour point gear oil with good low-temperature fluidity to prevent insufficient lubrication during startup.

Speed difference: High speed reducers (such as motor direct connected high-speed reducers) require low viscosity oil to reduce mixing resistance and temperature rise; Low speed reducers (such as low-speed high torque output types) require high viscosity oil to ensure the thickness of the oil film on the tooth surface.

3. Distinguish by installation and sealing form

Oil bath lubrication vs circulating lubrication: oil bath lubricated reducers have high requirements on oil foam resistance to prevent foam in operation from causing false high oil level and lubrication failure; Gearboxes with cyclic lubrication (such as large heavy-duty equipment) can use oil with good flowability and control the oil temperature with a cooling system.

Differences in sealing performance: Old style reducers with poor sealing performance require the use of slightly higher viscosity oil to reduce leakage; A well sealed gearbox (such as IP65 protection level) can flexibly choose viscosity according to working conditions.

Differences in installation methods: For vertically installed reducers, it is necessary to use oil with strong adhesion to prevent the loss of lubricating oil due to gravity, which may lead to insufficient lubrication of the upper gears/bearings; The horizontally installed reducer has relatively low requirements for oil adhesion.