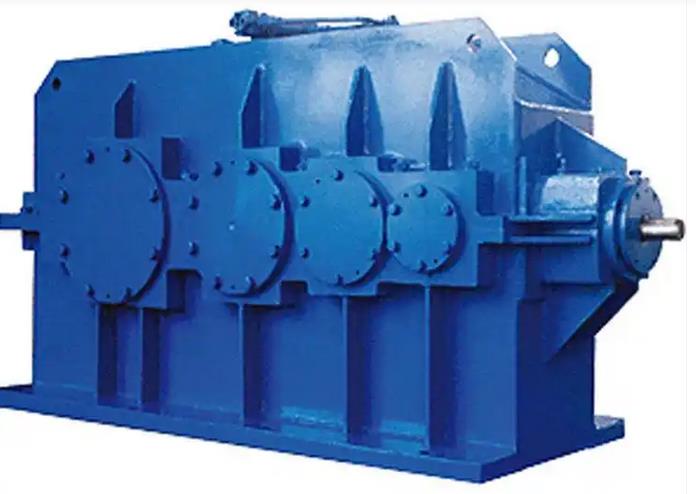

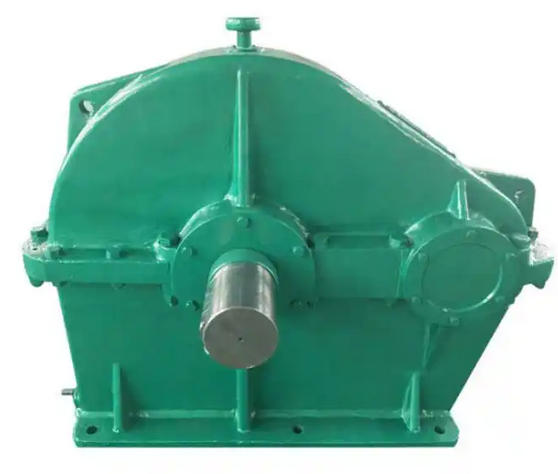

What tools are needed to retrofit a specific model ZD60-VI-4.5 gearbox

The modification of ZD60-VI-4.5 reducer requires the preparation of three major categories: disassembly tools, inspection tools, and processing auxiliary tools. The selection of tools should match the structural dimensions and accuracy requirements of the reducer model. The specific list is as follows, which can be directly compared for preparation:1. Basic disassembly and assembly tools

Socket wrench set (including 10~32mm specifications), torque wrench (range 0~300N · m, accuracy ± 3%): used for disassembling/tightening anchor bolts, flange bolts, and bearing end cap bolts, ensuring that the torque meets the requirements of the instruction manual.

Three claw puller (5-15t), hydraulic puller: used for disassembling interference fit components such as bearings, couplings, gears, etc., to avoid violent impact and damage to shaft components.

Copper rod and rubber hammer: assist in disassembling end caps and shells to prevent cracking of cast iron shells caused by hard impact.

Hexagonal wrench set (2-14mm), flathead/Phillips screwdriver: remove internal fastening screws and sealing covers.

Oil seal extractor and oil seal installation tool: Replace the input/output shaft oil seal to ensure that the oil seal lip is not scratched.

2. Precision testing tool

Frame level (accuracy 0.02mm/m): detects the flatness of the installed reference surface and shell after modification.

Dial gauge and gauge holder (range 0~10mm, accuracy 0.01mm), micrometer: measure gear mesh clearance, shaft radial runout, coaxiality error.

Feeler gauge (0.02~1mm): Check the gear side clearance and the fit clearance between the end cover and the housing.

Depth gauge and vernier caliper: measure the dimensions of modified components to ensure compatibility with the original factory structure.

3. Processing and auxiliary tools

Angle grinder, file, sandpaper (80-400 mesh): Polish the installation surface and flange end face after processing, remove burrs and oxide layer.

Grinding paste and grinding plate: Hand grind high-precision bonding surfaces to ensure sealing performance.

Anhydrous ethanol, acetone, dust-free cloth: Clean the oil stains and impurities inside the shell and on the surface of the parts.

Sealing glue (oil resistant type), copper gasket: used for sealing modified flanges and end caps to prevent oil leakage.

Lifting straps and manual hoists: transport the reducer body and heavy components to avoid collision and damage.