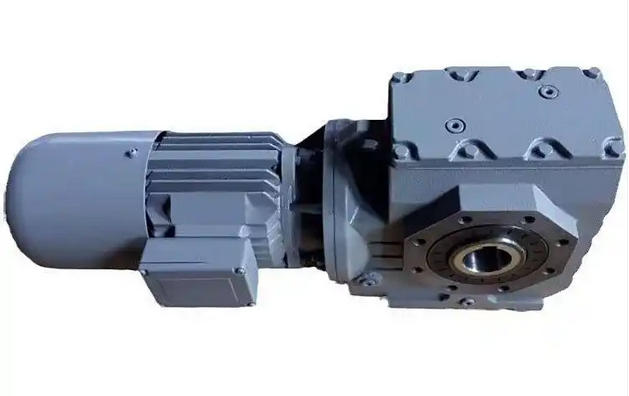

In the operating scenario of SA67AM90-85.83-M1 worm gear reducer, what are the specific aspects of working condition losses included

The operating losses of SA67AM90-85.83-M1 worm gear reducer mainly include the following aspects, and its mechanism of action is closely related to the characteristics of worm gear transmission:1、 Mechanical friction loss

1. Friction in tooth surface meshing

When the worm gear meshes with the worm wheel, the sliding friction coefficient is usually 0.08-0.121, and the friction loss accounts for 60% -70% of the total power. The equivalent friction angle (ρ) is directly related to the material combination (such as steel worm gear+bronze worm gear) and lubrication state.

2. Friction loss of bearings

The friction loss of worm shaft and output shaft bearings accounts for about 15% -20%, and the friction coefficient of deep groove ball bearings is 0.001-0.003. If the lubrication is poor (such as oil temperature>80 ℃) or the load exceeds the set value, the loss can increase by 30%.

2、 Fluid power loss

Oil mixing loss

The energy consumption generated by the stirring of lubricating oil by rotating components accounts for 5% -10%, which is proportional to the depth of the oil pool, the amount of oil, and the square of the rotational speed. For example, when the oil level is too high, stirring oil loss can increase by 20%.

Friction of sealing components

The friction loss between the oil seal lip and the shaft accounts for about 3% -5%. If the surface roughness of the shaft exceeds Ra0.8 μ m or the seal is aging, the loss will significantly increase.

3、 Thermodynamic loss

Efficiency decline caused by temperature rise

After continuous operation for 4 hours, the temperature rise Δ T should be ≤ 45K 4. If this limit is exceeded, the viscosity of the lubricating oil will decrease (such as VG320 oil, where the viscosity decreases by 50% at 100 ℃), and the friction loss will increase by 10% -15%.

Heat dissipation loss

The natural heat dissipation power on the surface of the shell accounts for about 2% -3% of the total input power. In dusty environments (such as mining conditions), the heat dissipation efficiency decreases by more than 30%.

4、 Additional loss under operating conditions

Overload and impact losses

When the instantaneous torque exceeds 1.2 times the rated value, the contact stress on the tooth surface increases sharply (such as from 800MPa to 1200MPa), and the additional loss can reach 2-3 times the normal value.

Environmental factor losses

High temperature (>120 ℃) or low temperature (<-20 ℃) environment causes lubricating oil failure, resulting in an increase of 25% -40% in friction loss; Dust intrusion causes abrasive wear, resulting in a 5% -15% decrease in efficiency.

5、 Improper maintenance and wear and tear

Lubrication failure

When lubricating oil is contaminated (metal particle content>50ppm) or deteriorated (acid value>0.5mgKOH/g), the risk of tooth surface bonding increases, and the efficiency decreases from 85% to below 50%.

Installation error loss

When the perpendicularity between the worm axis and the worm wheel axis exceeds 0.05mm/m, the local contact stress increases by 2-3 times, and the additional loss increases by 8% -12%.

In summary, the total efficiency (η) of this model of gearbox can be expressed as:

η=η₁ (meshing efficiency) × η₂ (bearing efficiency) × η ∝ (oil stirring efficiency), with a typical value of 70% -85%. Specific losses need to be measured and calibrated through torque sensors and power analyzers.