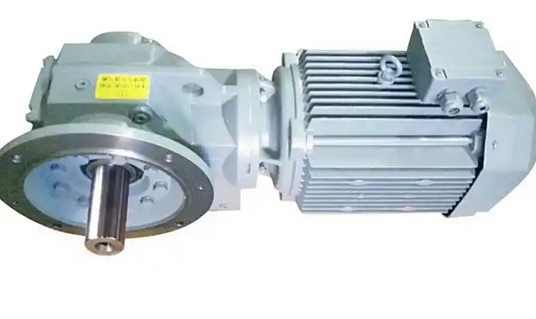

What should be noted when modifying a specific model ZD30-4-2 gearbox

When modifying the ZD30-4-2 gearbox, special attention should be paid to the three core aspects of structural adaptability, performance matching, and safety and reliability. Specific precautions are as follows:1. Clearly define the modification objectives and feasibility of the plan

Firstly, determine the purpose of the modification (such as increasing/decreasing speed, changing installation method, adapting to new loads), verify the original factory technical parameters, avoid exceeding the rated torque and speed range of the reducer after modification, and prevent gear and bearing overload failure.

2. Key points for modifying transmission components

If replacing gears or adjusting transmission ratios, it is necessary to ensure that the new gear module and pressure angle are consistent with the original factory, and the gear mesh clearance is controlled at 0.1-0.2mm. During installation, a dial gauge should be used to correct the coaxiality of the gears to prevent overloading; If bearings need to be replaced, they must be of the same model or equivalent precision products. It is prohibited to mix bearings of different brands and accuracies.

3. Installation Structure Modification Specification

If the installation method is changed (such as horizontal to vertical), a reliable support structure needs to be installed to ensure that the shell is evenly stressed; When reprocessing and installing flanges or bases, it is necessary to ensure that the perpendicularity between the flange end face and the input/output shaft is ≤ 0.05mm to avoid bending and deformation of the shaft system.

4. Lubrication and sealing system adaptation

If there are changes in the oil circuit and oil level after modification, the lubrication circuit needs to be redesigned to ensure sufficient lubrication of the gears and bearings; When replacing seals, it is necessary to choose materials that are suitable for the working conditions (such as nitrile rubber oil resistant, fluororubber temperature resistant) to prevent oil leakage; If the operating temperature increases after modification, it is necessary to upgrade the lubricating oil grade or install a cooling device.

5. Motor and load matching verification

If replacing the matching motor, it is necessary to ensure that the motor power and speed match the parameters of the modified gearbox, and the coaxiality error between the motor shaft and the gearbox input shaft is ≤ 0.05mm. The elastic coupling model needs to be re selected according to the new torque value, and the use of rigid couplings to transmit impact loads is prohibited.

6. Strength verification and safety protection

Perform strength verification on key components such as the modified housing and transmission shaft to avoid stress concentration; If exposed rotating parts are involved, protective covers should be installed to prevent safety accidents; After the modification is completed, a static or dynamic balance test is required to reduce operational vibration.

7. Trial operation verification

After modification, conduct a 2-4 hour no-load test run to monitor whether the temperature rise (≤ 80 ℃), vibration, and noise are normal; After gradually loading to the rated load and confirming that there are no abnormalities, it can be put into formal use.