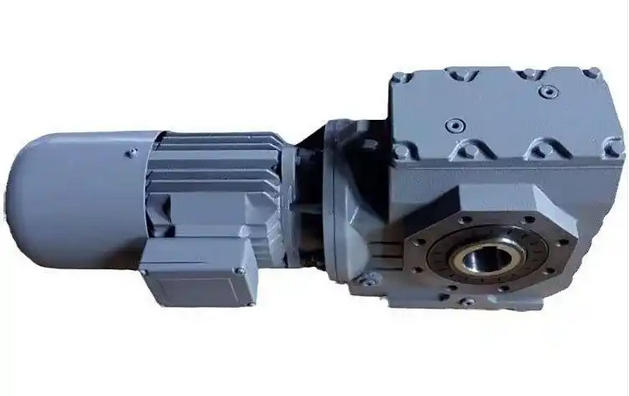

How to confirm whether the motor direction of BLD09-43-0.37KW cycloidal pinwheel reducer is correct

BLD09-43-0.37KW is a horizontal direct coupled cycloidal pinwheel reducer. The direction of motor rotation directly affects the running direction of the equipment load end and the internal force state of the reducer. It is necessary to follow the three-step method of "no-load verification, marking comparison, and load review" for confirmation. The specific operation is as follows:1. Preliminary preparation and safety regulations

Confirm that the reducer is disconnected from the driven equipment (if connected, the coupling or transmission components need to be removed) to avoid damage to the load end equipment caused by incorrect steering;

Check if the lubricating oil level of the reducer is within the specified range, manually rotate the output shaft to confirm that it rotates flexibly without any jamming;

Ensure that the motor wiring is correct and well grounded, inform surrounding personnel before powering on, and prepare emergency stop devices.

2. Label reference direction and no-load trial operation

Mark a clear reference point (such as a radial straight line) on the output shaft end face of the reducer with a marker pen, and at the same time mark a fixed point at the corresponding position on the machine base for easy observation of the steering direction;

Using a jog power on method (release immediately after pressing the start button, power on time ≤ 2 seconds), observe the direction of rotation of the output shaft reference point;

If the reference point rotates in the same direction as the specified direction in the equipment manual (usually clockwise or counterclockwise, judged by facing the output shaft), it is preliminarily judged that the direction of rotation is correct.

3. Multi round verification and steering correction

Repeat the jog operation 2-3 times to confirm that the steering is stable and there is no change, in order to avoid misjudgment of inertia caused by a single jog;

If the steering is incorrect, stop the machine and cut off the power supply, adjust the motor wiring phase sequence: for three-phase asynchronous motors, simply swap the wiring positions of any two power lines, and then re tap to verify;

After turning correctly, a no-load continuous test run (lasting 5-10 minutes) can be carried out to observe whether the noise and oil temperature of the gearbox are normal. If there are no abnormalities, the steering confirmation is completed.

4. Recheck after connecting the load end

Reconnect the reducer to the driven equipment to ensure that the coaxiality of the coupling meets the standard;

Conduct a load test run, observe whether the direction of operation of the load end equipment meets the process requirements, and monitor the vibration, temperature rise, and load current of the reducer. If there are no abnormalities, the final confirmation is that the steering is correct.