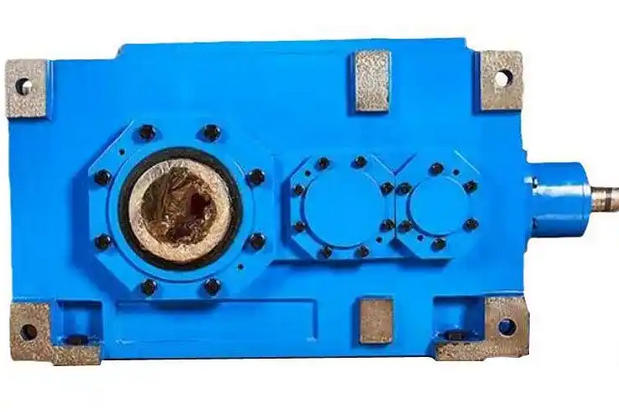

Is it necessary to replace the entire component after the NGW41-3.5 planetary gear reducer base cracks

After the NGW41-3.5 planetary gear reducer base cracks, there is no need to directly replace the entire component. The core judgment criteria are the severity, location, and feasibility of repair of the crack. Most minor to moderate cracks can be repaired to meet the standard, and only severe damage needs to be replaced.1. No need to replace (repairable) situation

Slight cracks: length<50mm, not penetrating the wall thickness, and not extending to key stress bearing parts such as bearing seats and bolt holes.

Medium crack: 50-150mm in length, penetrating through the wall thickness, but can be repaired through crack stopping holes, welding, and reinforcement (such as adding steel plates), and the original machine base strength can be restored after repair.

No accompanying damage: The machine base has no severe deformation, the dimensions of key mating surfaces (bearing seat holes, installation surfaces) do not exceed the tolerance, and the material has not suffered extensive fatigue damage due to cracks.

2. It is recommended to replace the entire machine base

Severe cracks: with a length greater than 150mm, or spreading to core parts such as bearing seats, anchor bolt holes, and box joint surfaces, the bearing stability cannot be guaranteed after repair.

Machine base deformation/size deviation: Cracks cause deviations in key mating surfaces of the machine base (such as bearing seat hole roundness and installation surface flatness) beyond the original drawing requirements (usually>0.05mm/m), which cannot be corrected through machining.

Material fatigue or multiple defects: The machine base has multiple scattered cracks, or the casting itself has original defects such as sand holes and air holes, which are prone to cracking again after repair.

High repair cost: The repair cost (including materials, labor, and downtime losses) is close to or exceeds the purchase cost of the new machine base, and the cost-effectiveness is too low.

3. Key decision-making principles

Priority assessment of repair feasibility: For minor to moderate cracks, welding, bonding, and other repair methods are preferred. After repair, non-destructive testing and load verification are required to confirm compliance.

Strict cracking in core areas: Cracks involving key stress concentration areas such as bearing seats and bolt holes, if the assembly accuracy and load-bearing capacity cannot be guaranteed after repair, will be replaced directly.