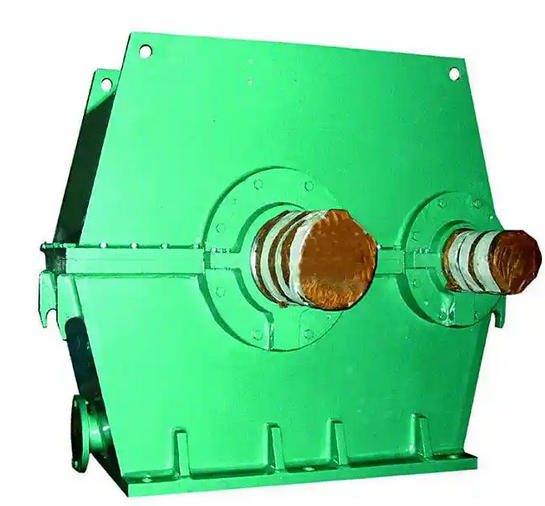

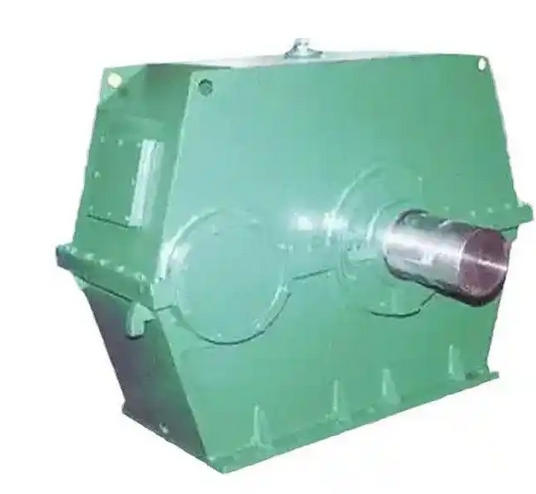

Compare the performance advantages of MBY500-4.5-2 hard tooth gear reducer and MBY450-5.6 reducer

MBY500-4.5-2 and MBY450-5.6 hard tooth surface gear reducers share common advantages such as hard tooth surface and high precision, but there are differences in specific performance. The following is a comparison of their performance advantages:Load capacity: Generally, the larger the model of the gearbox, the stronger its load capacity. The center distance of MBY500-4.5-2 is 500mm, and the center distance of MBY450-5.6 is 450mm. Therefore, MBY500-4.5-2 has a relatively larger load-bearing capacity and can withstand greater input power and output torque, making it more suitable for working conditions with larger loads.

Transmission ratio: The transmission ratio of MBY500-4.5-2 is 4.5, and the transmission ratio of MBY450-5.6 is 5.6. MBY500-4.5-2 has a higher output speed than MBY450-5.6 when the input speed is the same, making it more suitable for devices with certain requirements for output speed; MBY450-5.6 can provide greater speed reduction and torque increase, making it suitable for situations that require low speed and high torque.

Volume and weight: The overall size and weight of MBY500-4.5-2 are relatively larger than MBY450-5.6. MBY450-5.6 has better adaptability in situations where installation space is limited or there are strict restrictions on the overall weight of the equipment, and installation and maintenance may be relatively more convenient.

Gear accuracy and transmission efficiency: Both have gear accuracy above level 6 (GB10095) and adopt a single-stage reduction design. The comprehensive transmission efficiency of each gear stage is relatively high, reaching around 0.98. However, due to the relatively large gear size of MBY500-4.5-2, its gear contact strength and wear resistance may be better under the same manufacturing process and materials.