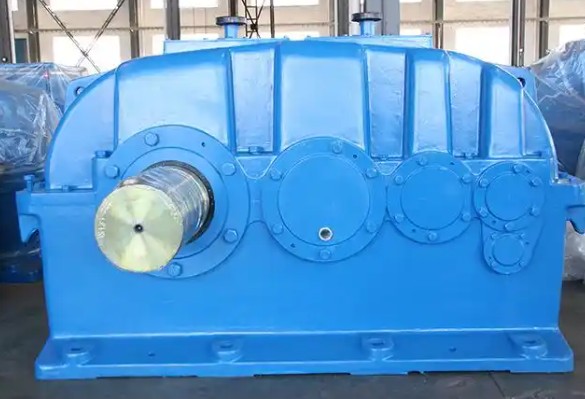

How to reduce the vibration of ZFY250-250-I gear reducer box

To reduce the vibration of the ZFY250-250-I hard tooth cylindrical gear reducer housing, it is necessary to start from five core dimensions: installation accuracy, load matching, lubrication status, structural reinforcement, and component maintenance. This model is a medium to heavy-duty and high transmission ratio reducer, and the vibration is often caused by installation deviation, load impact, and component wear. The specific measures are as follows:1. Improve installation foundation and coaxiality accuracy

Strengthening the rigidity of the foundation: The installation base should be welded with steel or cast iron platform, and the flatness error of the foundation should be ≤ 0.03mm/m; Install shock-absorbing pads or rubber isolators between the base and foundation to reduce the transmission of vibration to the box; The anchor bolts are made of 8.8 grade high-strength bolts, equipped with anti loosening washers, and tightened diagonally at the rated torque to prevent the base from loosening.

Strictly control coaxiality deviation: the radial deviation between the input end and the motor shaft, and the output end and the load shaft should be ≤ 0.05mm, and the angular deviation should be ≤ 0.1 °/100mm. Elastic couplings (such as plum blossom couplings) should be preferred to compensate for installation deviations and avoid additional loads caused by rigid connections that can cause box vibration.

2. Optimize load and operating conditions

Avoid overloading and impact loads: It is strictly prohibited to operate beyond the rated torque for a long time. If the load fluctuates greatly (such as crushers and conveyors), a torque limiter should be installed; Control the start stop frequency of the equipment, with a start stop interval of ≥ 5 seconds, to avoid inertial impact caused by frequent forward and reverse rotation; For load starting conditions, a soft starter or frequency converter can be installed to ensure smooth loading.

Ensure even load transmission: Check if the connection between the output shaft and the load is eccentric. If it is a belt wheel or chain wheel drive, ensure the verticality of the belt wheel/chain wheel to prevent one-sided force from causing box vibration; Regularly check the dynamic balance of load equipment (such as impellers and drums), as excessive imbalance can cause periodic vibrations to be transmitted to the casing.

3. Improve lubrication and gear meshing status

Select suitable lubricating oil: It is recommended to use 320 # medium load industrial gear oil for this type of reducer, which should have good anti-wear and anti emulsification properties; The oil level should be maintained at 1/2~2/3 of the oil gauge scale. Insufficient oil level can cause poor gear meshing, while excessive oil level can increase stirring resistance, both of which can exacerbate vibration.

Regular inspection of gear meshing accuracy: After 10000 hours of operation, disassemble and inspect the gear tooth surface. If there is pitting, peeling, or tooth thickness wear exceeding 5% of the original tooth thickness, the gear should be replaced in a timely manner; Adjust the gear mesh clearance to ensure that the mesh side clearance is between 0.15~0.3mm (refer to the manufacturer's manual for details). Poor meshing can cause high-frequency vibration.

4. Strengthen the box structure and maintain its components

Box structure reinforcement: If the box wall is thin, reinforcement ribs can be welded on the outside of the box (arranged along the axial and radial directions of the box) to enhance the rigidity of the box and reduce resonance; Check the bolts of the box body and tighten them again according to the rated torque. If there is any leakage on the box body surface, apply sealant again to prevent vibration caused by loosening of the box body surface.