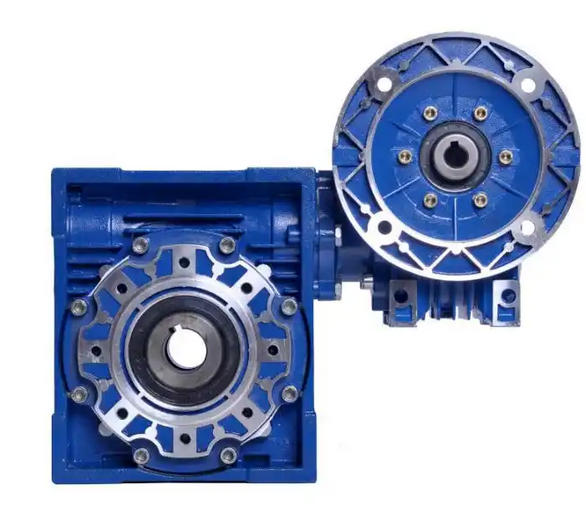

How to repair WHC160-10 worm gear reducer bearings after damage

The WHC160-10 model is suitable for small and medium-sized loads, with bearings as the core load-bearing components. After damage, it needs to be repaired according to the "shutdown inspection disassembly cleaning replacement assembly testing and trial operation" process. The core controls the three key aspects of coaxiality, clearance, and lubrication to prevent secondary damage1. Pre preparation and shutdown safety confirmation (maintenance prerequisite, indispensable)

1.1 Shutdown and power off, hang maintenance signs, cut off the connection between the reducer, motor, and load end to prevent safety accidents caused by misoperation

1.2 Prepare adaptation tools: puller, bearing heater, torque wrench, plug gauge, dial gauge, cleaning agent, lubricating grease, and prepare bearings that are compatible with WHC160-10 (priority should be given to the same model from the original factory, commonly used models are deep groove ball bearings/self-aligning roller bearings, and the shaft diameter size needs to be matched)

1.3 Troubleshooting of bearing damage to avoid misjudgment: abnormal running noise (buzzing/metal friction sound), abnormal temperature rise (bearing temperature>80 ℃), excessive shaft end jumping, severe box vibration, and metal debris in the lubricating oil. If one of these conditions is met, bearing damage can be determined

2. Disassembly process (operate in sequence to avoid damaging the body)

2.1 First, empty the gear oil in the box, unscrew the oil port plug, thoroughly drain the old oil, collect and seal it for processing, and prohibit arbitrary discharge

2.2 Disassembling external connectors: Remove the flange connecting bolts between the motor and the reducer, the load end coupling/flange, remove the anchor bolt fixing parts, and smoothly lift the reducer to the maintenance platform

2.3 Disassembling box components: Unscrew the bolts on the upper and lower joint surfaces of the box, use a top screw to separate the upper and lower boxes, make alignment marks (to avoid assembly misalignment), take out the worm gear and worm assembly, handle gently to prevent collision with the tooth surface

2.4 Disassemble damaged bearings: First remove the bearing end cover, sealing ring, and retaining ring, and use a puller to smoothly pull out the damaged bearing. Violent tapping is strictly prohibited (to prevent deformation of the shaft neck); If the interference fit of the bearing is too tight, use a bearing heater to heat it to 80-100 ℃ before disassembling, and avoid scalding during heating

2.5 Cleaning and disassembling components: Thoroughly clean the shaft neck, bearing seat hole, end cover, and retaining ring with cleaning agent, remove oil stains, metal debris, and rust, wipe dry, and check the condition of the components