What are the application scenarios of RV90 and RV75 worm gear reducers

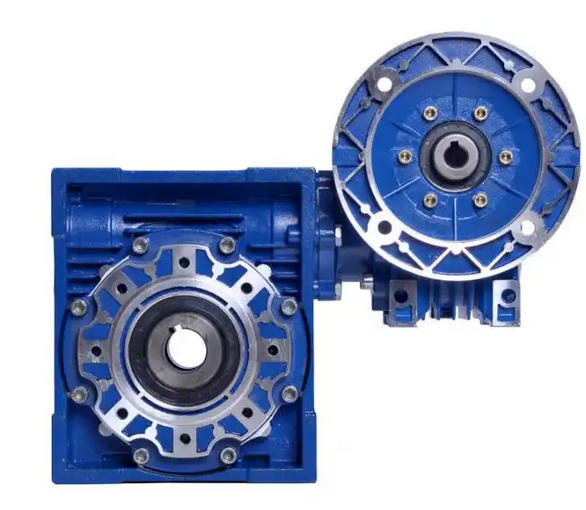

Application scenarios of RV90 and RV75 worm gear reducersRV75 and RV90 belong to the RV series small worm gear reducer, with core differences in center distance, load-bearing capacity, and adaptive power. The application scenarios need to be divided based on load size, installation space, and working condition intensity, as follows:

1、 Application scenarios of RV75 worm gear reducer

RV75 has a center distance of 75mm, a rated torque range of 12-480N · m, a suitable power of 0.09-4kW, small size and light weight, suitable for light load, compact space, and medium low speed working conditions:

1. Small automation equipment: conveyor belt drive for electronic component assembly lines, PCB board conveyor mechanism, sorting arm drive for small sorting machines, utilizing their small size advantages to adapt to compact equipment layouts.

2. Light industry packaging machinery: small sealing machine pressure roller drive, quantitative feeding mechanism for milk tea/beverage filling machine, film traction system for food pillow packaging machine, meeting the uniform transmission requirements of light load and low impact.

3. Medical equipment and laboratory equipment: deceleration drive for small sample centrifuges, lifting and adjusting mechanism for medical beds, power transmission for laboratory mixers, low operating noise, suitable for high-precision and low vibration scenarios.

4. Doors, windows, and ventilation equipment: small electric louver drives for industrial plants, deceleration mechanisms for automatic sliding doors, angle adjustment for small ventilation valves, low load and low operating frequency, no need for high load redundancy.

5. Small conveying and lifting equipment: workshop lightweight material conveyor belt (load<200kg), electroplating plant small hanging tool lifting mechanism, drawer push-pull drive for storage small containers, meeting short-term, light load lifting or conveying needs.

2、 Application scenarios of RV90 worm gear reducer

RV90 has a center distance of 90mm, a rated torque range of 22-850N · m, and a suitable power of 0.09-7.5kW. It has stronger load-bearing capacity and better impact resistance, and is suitable for medium to heavy load, high-frequency start stop, and high power working conditions:

1. Automated warehousing and logistics equipment: The lifting and translation drive of small forks in three-dimensional warehouses, the walking deceleration mechanism of AGV carts, and the sorting push rod drive of medium-sized sorting machines can withstand frequent start stop impact loads.

2. Packaging and Printing Machinery: The cardboard conveying drive for medium-sized cardboard box forming machines, the paper feeding mechanism for label printing machines, and the deceleration system for bottle sorting machines in bottled beverage production lines meet the transmission requirements for medium load and continuous operation.

3. Building materials and light industry machinery: The power deceleration of small tile cutting machines, the drive of conveyor rollers in gypsum board production lines, and the feed mechanism of door and window profile cutting equipment can withstand certain cutting impact loads.

4. Lifting and hoisting equipment: The hoisting mechanism of small workshop cranes (load<500kg), the drive system of the lifting platform, and the parking space lifting mechanism of the three-dimensional garage rely on higher torque output and operational stability.

5. Agricultural and environmental protection equipment: deceleration drive for small feed mixers, lifting mechanism for small picking platforms in orchards, transmission system for small scraper in sewage treatment equipment, suitable for harsh outdoor or dusty working conditions.