What are the applicable working conditions of ZL115-8 gear reducer?

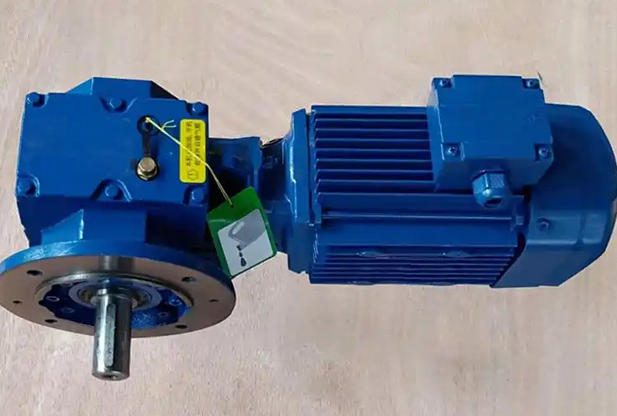

The ZL115-8 gear reducer belongs to the ZL series two-stage cylindrical gear reducer. In the model, "115" represents the final center distance of 1150mm, and "8" represents the nominal transmission ratio of 8. According to JB/T 8853-2015 "Cone Gear Cylindrical Gear Reducer" and practical application experience, its applicable working conditions are as follows:1. Speed and motion conditions

The rated input speed of the high-speed shaft is ≤ 1500r/min, suitable for 4-pole and 6-pole standard asynchronous motors (corresponding to speeds of 1500r/min and 1000r/min). Under special working conditions, it can withstand a peak speed of no more than 1800r/min for a short period of time, with a duration of no more than 30 minutes; The circumferential speed of the gear is ≤ 20m/s, and the output shaft speed can be calculated using the formula (output speed=input speed ÷ 8). It is suitable for constant speed transmission scenarios that require high speed stability, but not suitable for high-frequency variable speed and stepless speed regulation conditions.

2. Load and power conditions

Suitable for medium to heavy steady loads or slight impact loads, with a rated input power range typically from 15kW to 160kW (specific values to be determined in the manufacturer's selection manual); Short term overload operation is allowed, with an overload rate of ≤ 120% of the rated load, a single overload duration of ≤ 15 minutes, and an interval of ≥ 1 hour between two overloads. The frequency of forward and reverse rotation should be ≤ 10 times/hour, and long-term frequent forward and reverse rotation or severe impact loads are strictly prohibited. It is suitable for power transmission of equipment such as conveyors, mixers, and bucket elevators.

3. Environmental and temperature conditions

The working environment temperature range is -40 ℃~45 ℃. When the ambient temperature is below 0 ℃, the lubricating oil must be preheated to above 10 ℃ before starting to prevent difficulty caused by high viscosity of the lubricating oil; When the ambient temperature exceeds 45 ℃, a forced cooling device (cooling fan or water cooling jacket) should be installed, and the lubricant replacement cycle should be appropriately shortened; It can be used in environments with high dust and humidity (relative humidity ≤ 90%, no condensation). If it is used in situations containing salt spray or corrosive gases, the gearbox body needs to be treated with anti-corrosion coating (such as spraying epoxy zinc rich paint).

4. Installation and layout conditions

Supports various assembly types such as horizontal and vertical, and can be installed with foot, flange, or shaft. During installation, it is necessary to ensure that the coaxiality error between the input shaft and the motor shaft is ≤ 0.1mm, and the axis inclination angle of the two shafts is ≤ 0.5 °, to avoid early bearing wear and poor gear meshing caused by excessive coaxiality; Suitable for the basic installation of fixed equipment, not recommended for working conditions such as strong vibration and frequent movement of construction machinery walking mechanisms.

5. Industry and equipment adaptation conditions

(1) Metallurgical industry: roller conveyors, bin feeders, and finished product sorting equipment that can be used in steel rolling production lines to meet the needs of 24-hour continuous work and stable operation under heavy loads;