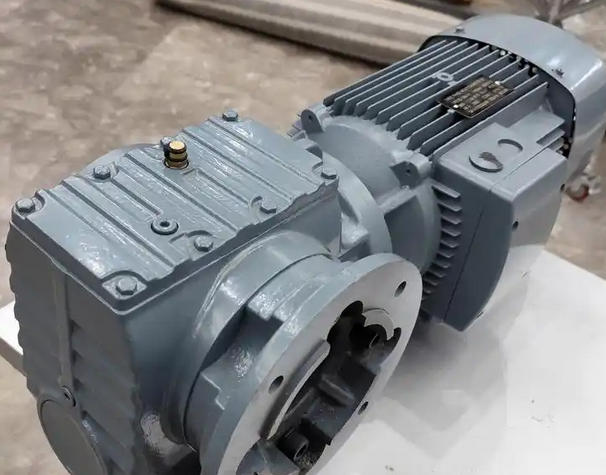

How to perform rust prevention treatment on the heat dissipation area of KAF67-5.5KW-15.75-M5 gear reducer after cleaning

KAF67-5.5KW-15.75-M5 gear reducer cooling area cleaning and rust prevention treatment planThe heat dissipation structure of KAF67 series gear reducers (mostly consisting of heat sinks/ribs+outer surface of the housing) is the core of equipment heat dissipation. After cleaning, residual moisture and cleaning agents can easily cause metal corrosion, thereby affecting heat dissipation efficiency and housing structural strength. The following is a specialized rust prevention process for this model of gearbox, which balances practicality and long-term protection:

1. Basic drying treatment after cleaning (core pre step)

After cleaning the heat dissipation area, it is necessary to thoroughly remove moisture to avoid residual moisture from causing electrochemical corrosion:

Priority should be given to using compressed air for drying: Use 0.4-0.6MPa dry compressed air to blow from top to bottom and from inside to outside along the gaps between the heat sinks (the spacing between this model of heat sink is about 8-12mm), with a focus on cleaning dead corners such as the root of the heat sink, the connection between the shell and the heat sink ribs, to ensure that there is no residual water accumulation; If water-based cleaning agent is used during cleaning, it is necessary to additionally purge the cleaning agent foam residue in the gap of the radiator.

Assisted drying and enhanced drying: If conditions permit on site, place the reducer in a drying room at 60-80 ℃ and bake for 30-60 minutes, or use a hot air gun (set to medium temperature, 15-20cm away from the heat dissipation surface) to evenly blow for 20-30 minutes until there are no traces of moisture on the surface of the heat sink detected by test paper.

Alternative solution for natural drying: If compressed air or drying equipment cannot be used, the gearbox should be placed in a ventilated, dry, dust-free, and non corrosive gas environment for at least 4 hours, avoiding direct sunlight (to prevent aging of the shell paint surface) and contact with rainwater.

2. Surface degreasing and activation treatment (to enhance the adhesion of the rust proof layer)

After drying, residual oil stains and cleaning agents on the surface need to be removed to ensure a tight bond between the rust proof material and the metal surface

Defatting treatment: Use industrial grade anhydrous ethanol or neutral degreasing agent, dip a clean cloth and gently wipe the surface of the heat sink and the connection of the housing, focusing on cleaning any oil stains that may remain during the cleaning process (such as gear oil leakage marks). After wiping, dry with a clean dry cloth to avoid residual degreasing agent.

Slight rust activation (if any): If there is already slight floating rust before cleaning, a metal surface activator (such as phosphate based activator) can be used to dip a cloth and gently wipe the rusted area. After removing the floating rust, immediately rinse it with clean water, and then thoroughly dry it according to step 1 to prevent the activator from corroding the metal surface.