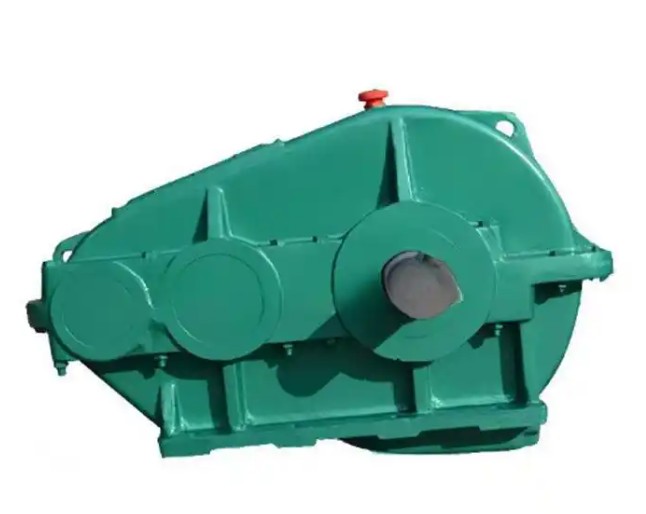

What preparations need to be made before the trial operation of ZQ400-48.57-3CA gear reducer

Core principle: Complete a comprehensive inspection, debugging, and safety confirmation before the trial operation to ensure that the equipment is installed in compliance, lubricated properly, connected firmly, and has complete safety protection, and there are no hidden dangers before starting. Follow the process of "external inspection ->internal inspection ->lubrication inspection ->connection debugging ->safety confirmation ->no-load trial machine review" to adapt to the installation and trial operation requirements of this model with hard tooth surfaces and accessories.1、 Review and inspection of foundation and installation dimensions

Check the installation base foundation of the reducer to ensure that the concrete foundation strength meets the standard, there is no cracking or sinking, the base is tightly attached to the foundation, and the gap has been filled with inclined iron/cement slurry. The horizontal deviation is ≤ 0.1mm/m (both longitudinal and transverse are rechecked);

Tighten the anchor bolts and confirm that all bolts are equipped with anti loosening washers. The tightening torque meets the equipment requirements (ZQ400 series anchor bolts have a torque of about 80-100N · m), and there is no looseness or slipping phenomenon;

Verify the installation center height of the reducer, the coaxiality of the input/output shaft, and match the installation dimensions of the motor and working machine without any misalignment or offset.

2、 Appearance and internal cleaning inspection of the body

Check that the gearbox body is free of deformation and cracks, and that the end caps and sealing gaskets on the joint surfaces are intact and undamaged. The accessories such as the oil level gauge, oil drain plug, and vent plug are installed completely and without missing parts;

Remove the fixed fixtures/positioning pins (such as input/output shaft protective covers, box fixing brackets) during transportation, and confirm that there are no transportation protection residues;

Open the observation hole cover plate and check that there are no foreign objects such as iron filings, sand and gravel, bolt fragments, etc. inside the box. The gear tooth surface should be free of bumps, burrs, and rust. The bearings should be installed in place without looseness or shaking, and the gear meshing surface should be free of abnormal damage;

Manually rotate the input shaft of the gearbox in both directions (3-5 turns each) to ensure smooth operation, no jamming, abnormal noise, or movement, and no obvious blockage in the bearing parts.

3、 Comprehensive inspection and filling of lubrication system

Confirm the matching of lubricant model: According to the requirements of ZQ400-48.57-3CA, add medium load industrial gear oil L-CKC320 (special for closed gearboxes), and prohibit the use of non-standard or deteriorated lubricants;

Clean the oil level gauge to ensure that the scale is clear and unobstructed. Slowly add lubricating oil until the oil level is between the centerline/upper and lower scales of the gauge, and it should not be too high (due to temperature rise) or too low (due to insufficient lubrication);

Check that the breathable plug is installed smoothly and unobstructed (to ensure pressure balance inside the box and prevent oil leakage), and that the sealing gasket of the oil drain plug is intact and tightened without leakage;

If the reducer is equipped with a forced lubrication system (this model CA includes accessories), check that the oil pump and oil pipe connections are firm and undamaged, manually test that the oil pump is running normally, the oil pipe is not blocked or leaking, and the lubrication point is supplying oil smoothly.