What are the differences between cycloidal pinwheel reducer and worm gear reducer in application scenarios

There are the following differences in application scenarios between cycloidal pinwheel reducers and worm gear reducers:Accuracy requirements

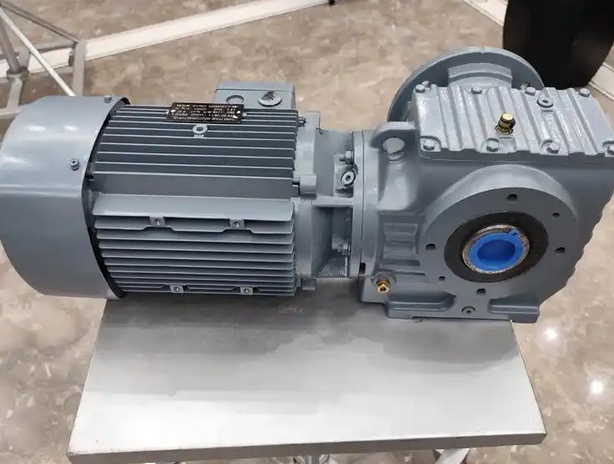

Cycloid pinwheel reducer: High transmission accuracy, small backlash and backlash, imported ones can usually be controlled within 10 arc minutes. Suitable for applications that require high precision, such as conveyor belts, robotic arms, joint drives for robots in industrial automation equipment, as well as drive systems for CT scanners, X-ray machines, and other medical equipment. It can ensure high-speed, stable operation, and precise positioning of the equipment.

Worm gear reducer: It is difficult to control the backlash, and after long-term running in, the backlash is relatively large, usually in degrees. So it is not very suitable in some scenarios that require extremely high transmission accuracy, but in some situations where accuracy requirements are relatively low, such as material hoists and stage lifting devices in construction, its accuracy can meet the requirements.

Self locking requirement

Cycloid pinwheel reducer: generally does not have self-locking function.

Worm gear reducer: It has a reverse self-locking function, which gives it a unique advantage in some situations that require self-locking, such as lifting machinery. When a heavy object is lifted to a specified height, even if the motor stops running, the self-locking function of the worm gear can ensure that the heavy object hovers steadily, eliminating the risk of heavy object sliding down.

Speed and torque

Cycloid pinwheel reducer: With a moderate reduction ratio, it can reduce speed and increase torque to a certain extent, making it suitable for high-speed applications and achieving high transmission efficiency. Commonly used in equipment that requires high rotational speed and moderate torque, such as mixers and conveyor belts in the food processing industry, they require relatively high operating speeds to ensure production efficiency while providing sufficient torque to drive loads.

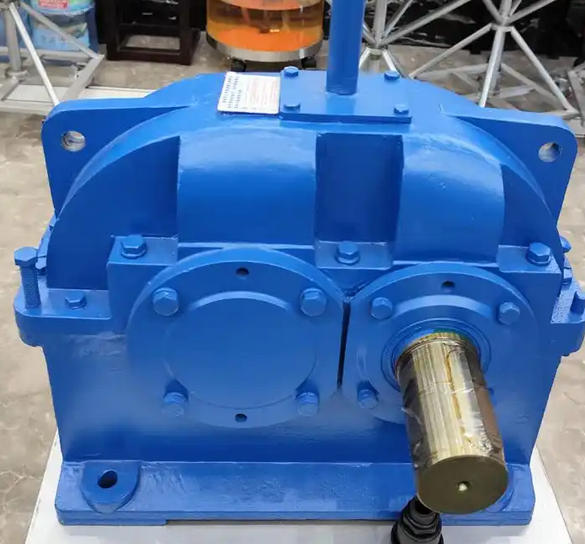

Worm gear reducer: With a large reduction ratio, it can significantly reduce the speed of the motor and output a large torque, making it suitable for low-speed and high torque situations. For example, heavy equipment such as crushers and ball mills in mining require a large amount of torque to crush and grind ores, while requiring relatively low rotational speed.