Introduce the working principle of ZDY355-5.6-II gear reducer

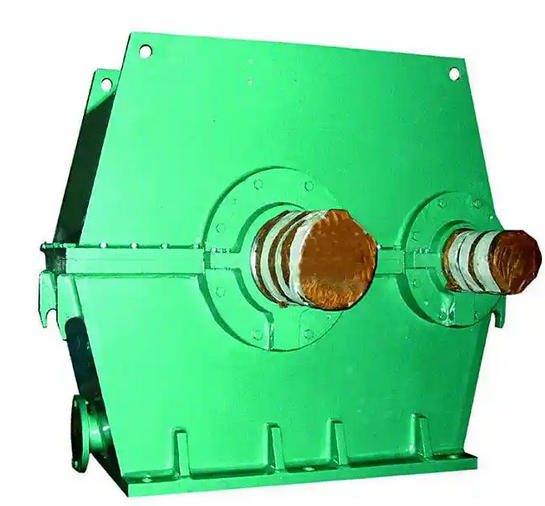

ZDY355-5.6-II gear reducer belongs to single-stage hard tooth parallel axis gear reducer, and its working principle is based on the basic principle of gear transmissionThe specific details are as follows:

Deceleration principle: The input shaft of the reducer is connected to a power source such as an electric motor, and a small gear is installed on the input shaft. When the input shaft rotates, the small gear also rotates and meshes with the large gear on the output shaft. Due to the fact that the number of teeth on the large gear is greater than that on the small gear, according to the characteristics of gear transmission, when the small gear drives the large gear to rotate, the speed of the large gear will be lower than that of the small gear, thereby achieving deceleration. In the ZDY355-5.6-II gear reducer, "355" usually represents the center distance, and "5.6" is the nominal transmission ratio, which is the ratio of the input shaft speed to the output shaft speed. This means that when the input shaft rotates at a certain speed, the output shaft speed will decrease to about 1/5.6 of the input shaft speed.

Principle of torque increase: According to the law of conservation of energy, while decelerating, the torque on the output shaft will correspondingly increase. The torque output ratio is roughly calculated by multiplying the motor output torque by the reduction ratio, but cannot exceed the rated torque of the gearbox. For example, if the motor output torque is T and the reduction ratio is 5.6, theoretically the torque of the gearbox output shaft will reach around 5.6T. However, in practical applications, factors such as the efficiency of the gearbox need to be considered, and the output torque will be slightly lower than the theoretical value. This enables the ZDY355-5.6-II gear reducer to provide greater torque for the working machine to meet the requirements of low-speed and high torque operation.

Power transmission principle: Power is transmitted from the input shaft to the output shaft through the meshing of the gear pair. In this process, the tooth surfaces of the gears come into contact with each other and transmit force and motion, converting the high-speed rotational motion of the electric motor into low-speed rotational motion of the output shaft, while achieving torque amplification, thereby driving the working machine to operate. In order to ensure the smoothness and reliability of power transmission, the gears of ZDY355-5.6-II gear reducer are usually made of high-quality 20CrMnMo alloy steel forgings, which are treated with processes such as carburizing, quenching, and grinding to give the tooth surface high hardness and wear resistance. The gear accuracy can reach level 6, which can effectively improve contact accuracy, reduce vibration and noise, and ensure efficient and stable power transmission.

In addition, ZDY355-5.6-II gear reducers generally use oil pool splash lubrication and free cooling methods. When the thermal power cannot meet the requirements, circulating oil lubrication, fan cooling, or condenser lubrication can also be used to ensure that the reducer can receive good lubrication and cooling during operation, ensuring its performance and service life