The correct rotation direction and importance of using spiral bevel gear reducer

Spiral bevel gear reducer is a common transmission device widely used in mechanical equipment. The correct rotation direction is crucial when using this reducer. This article will start from the structural principle and working characteristics of the reducer, and explain in detail why it is important to pay attention to the correct rotation direction when using a spiral bevel gear reducer.

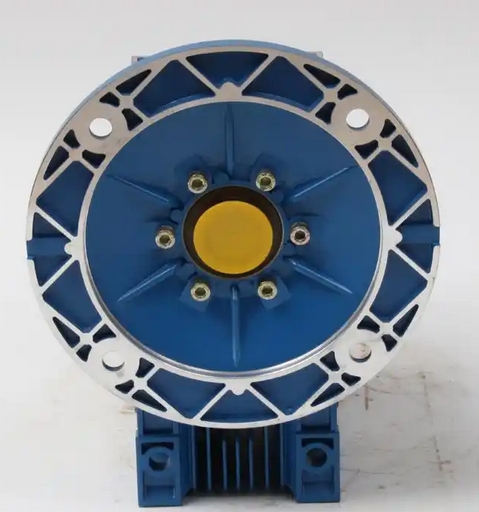

Before introducing the correct rotation direction, let's first understand the structural principle of the spiral bevel gear reducer. The spiral bevel gear reducer consists of an input shaft, an output shaft, and a spiral bevel gear. The input shaft and output shaft are respectively connected to the driving device and the driven device, and power is transmitted through the meshing of the spiral bevel gear. The characteristic of spiral bevel gears is that the tooth surface is helical, which can achieve larger transmission ratios and higher transmission efficiency.

Next, let's understand the working principle of the spiral bevel gear reducer. When the input shaft rotates, the spiral bevel gear begins to rotate, while driving the output shaft to rotate. This meshing method can effectively reduce the impact and noise during gear meshing, and improve the smoothness and reliability of transmission. However, if the rotation direction is not selected correctly, it will cause the gearbox to run in reverse and may even cause equipment damage.

To ensure the normal operation of the spiral bevel gear reducer, we need to pay attention to the correct rotation direction. The correct direction of rotation needs to be judged based on the actual situation and user needs. Generally speaking, when the reducer is used to drive axial loads, clockwise rotation should be chosen; When the reducer is used to drive axial positive loads or loads with rotational inertia, counterclockwise rotation should be selected. The correct rotation direction can make the reducer more stable during operation, improve the reliability and service life of the transmission.

In addition, the correct rotation direction can effectively avoid the danger of reverse operation. Reverse operation will cause the transmission direction of the reducer to be opposite to the requirements of the equipment, which may cause abnormal operation, damage, and even dangerous accidents of the equipment. Therefore, in order to ensure the safe operation of the equipment, we must pay attention to selecting the correct rotation direction.

In summary, the correct rotation direction is crucial for using a spiral bevel gear reducer. It can ensure the normal operation of the reducer, improve the reliability and service life of the transmission, and avoid the danger caused by reverse operation. When selecting the rotation direction, it should be judged based on the actual situation and user needs to ensure the safe operation and normal operation of the equipment.